Curved Fragments

A novel production technique for curved panels in architecture

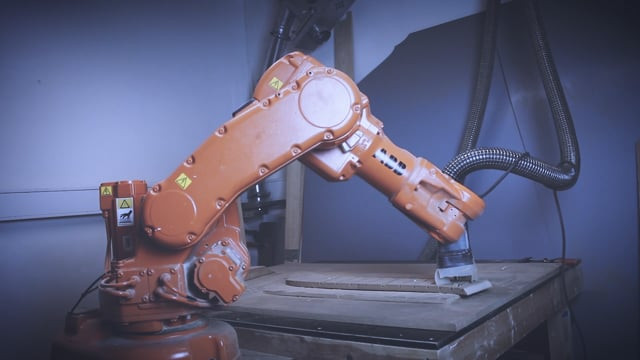

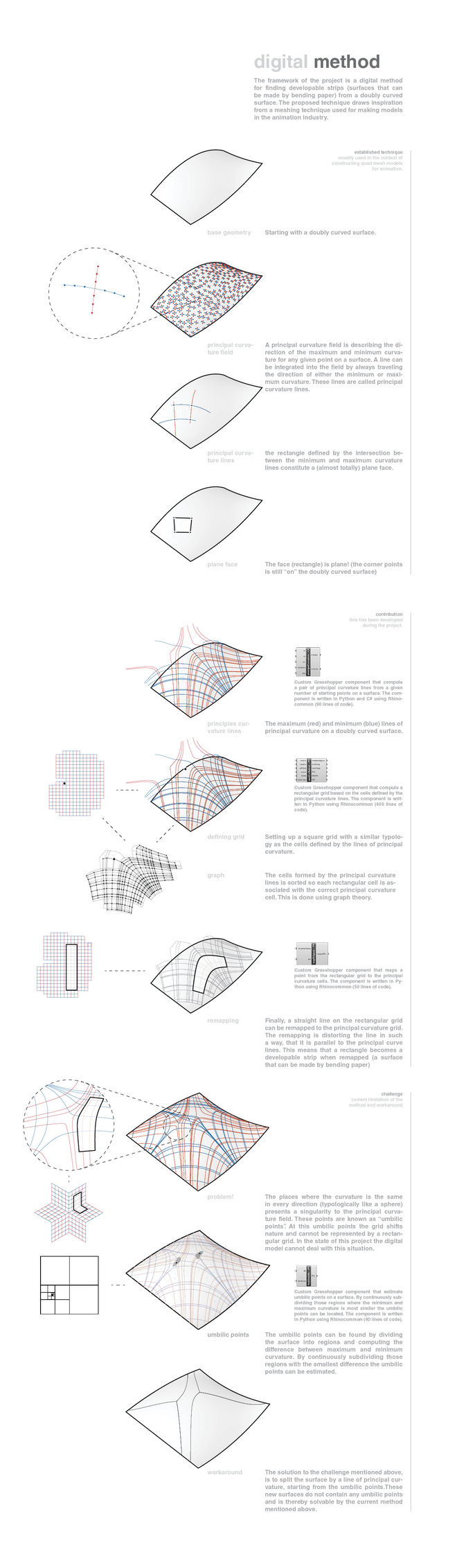

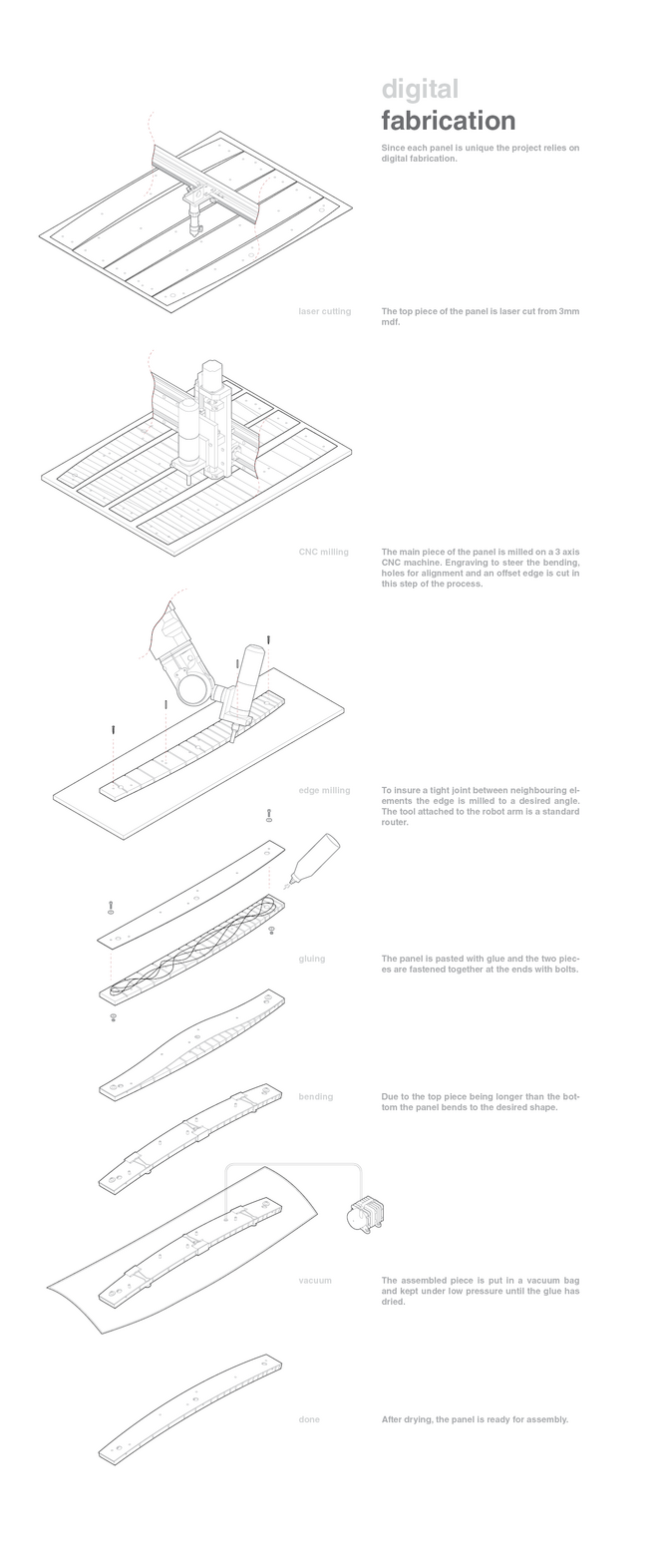

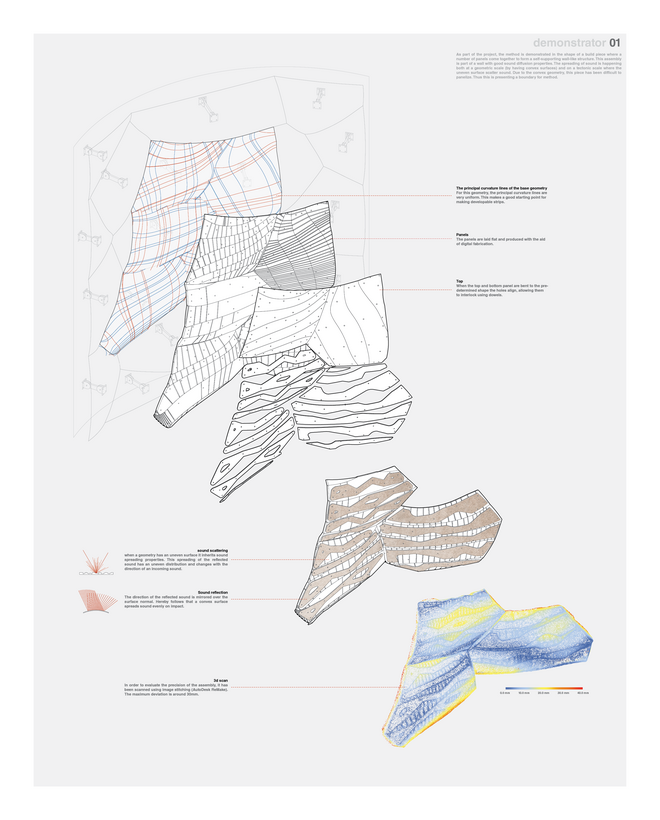

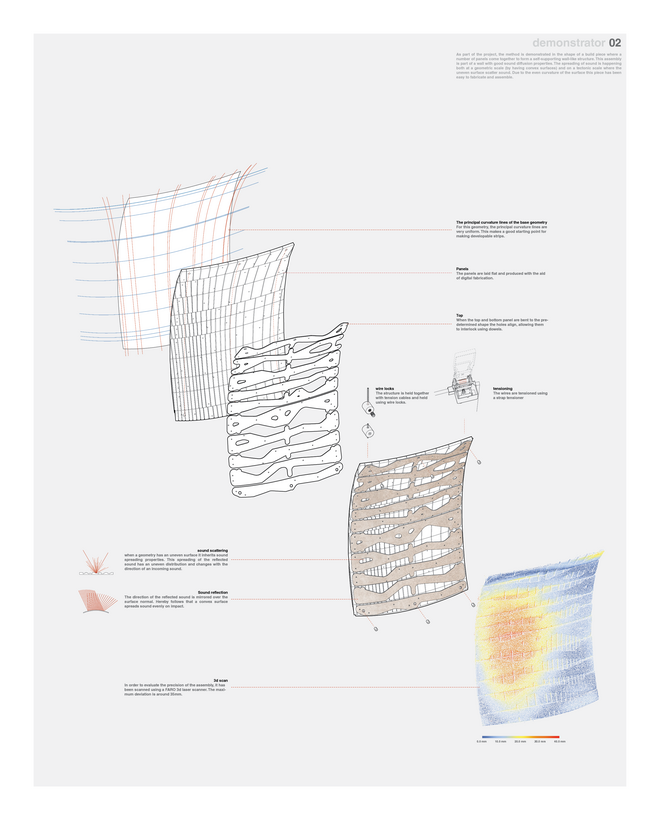

This project seeks to investigate a novel method for producing curved panels in architecture. Today curved building elements require extensive machining time and are subject to a large part of raw materials being wasted. In this project, I set out to investigate an alternative faster and thereby cheaper method where less material is wasted during production.

Method

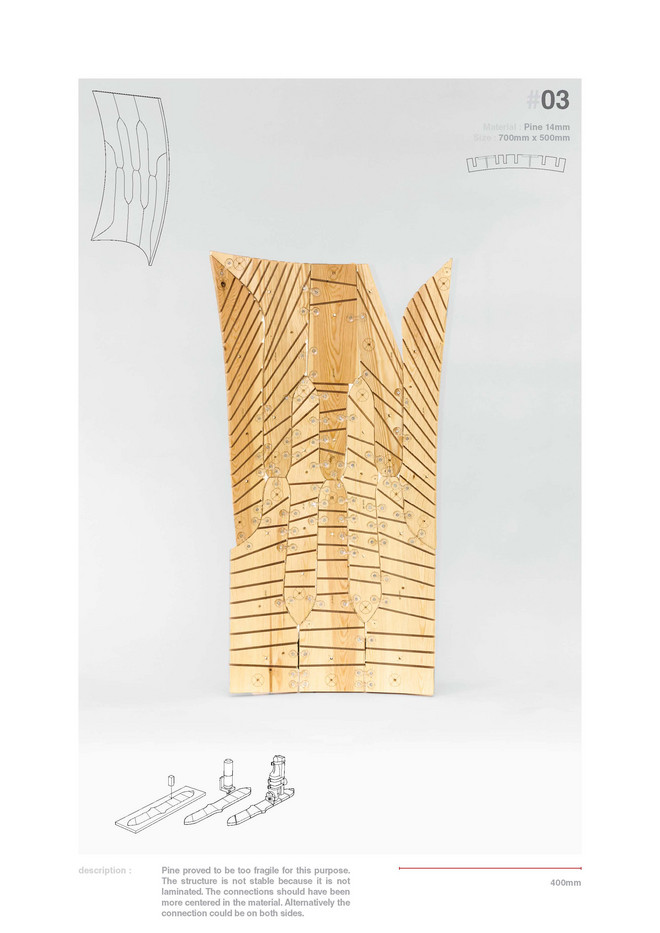

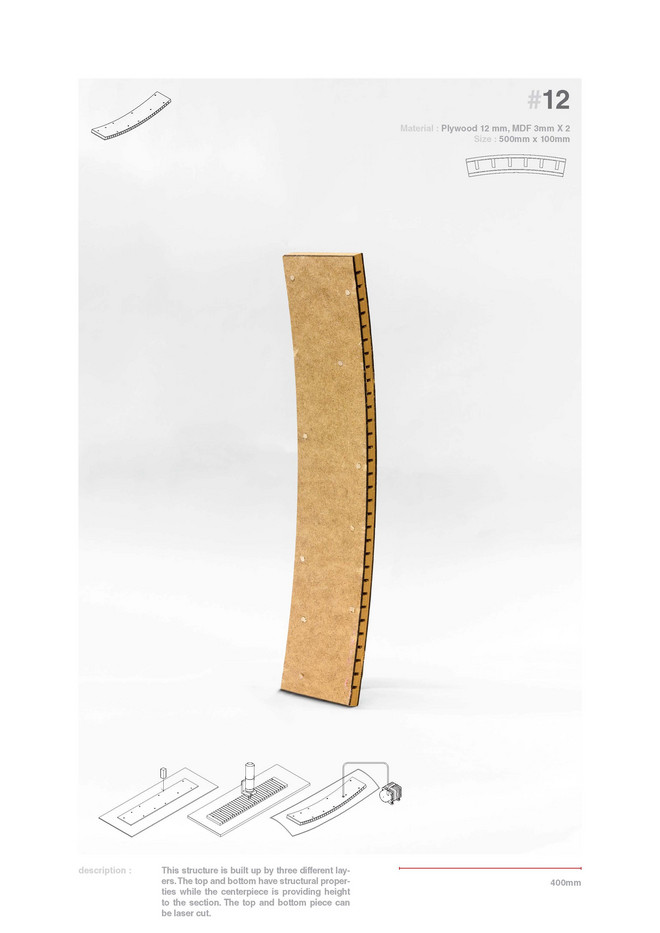

The method draws inspiration from Christoph Schindler’s zipShape research. In 2009 Schindler proposed a method for producing curved panels where the bending is given by “teeth” that fit together when the pieces are bend to the desired angle. This method is extremity elegant, however, it requires a lot of machining and is thereby relatively slow. The project provides a new strategy that requires less machining during production. Thus the method is relevant on an architectural scale. The investigations span from the digital (panelizing, finding “bending cuts” and producing fabrication files) across an understanding of material properties and robotic fabrication. The project ends out by speculating on the potential of the method in the context of a small concert hall.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål