Harmonious Morphogenesis: A geometric imperative for bent timber morphologies

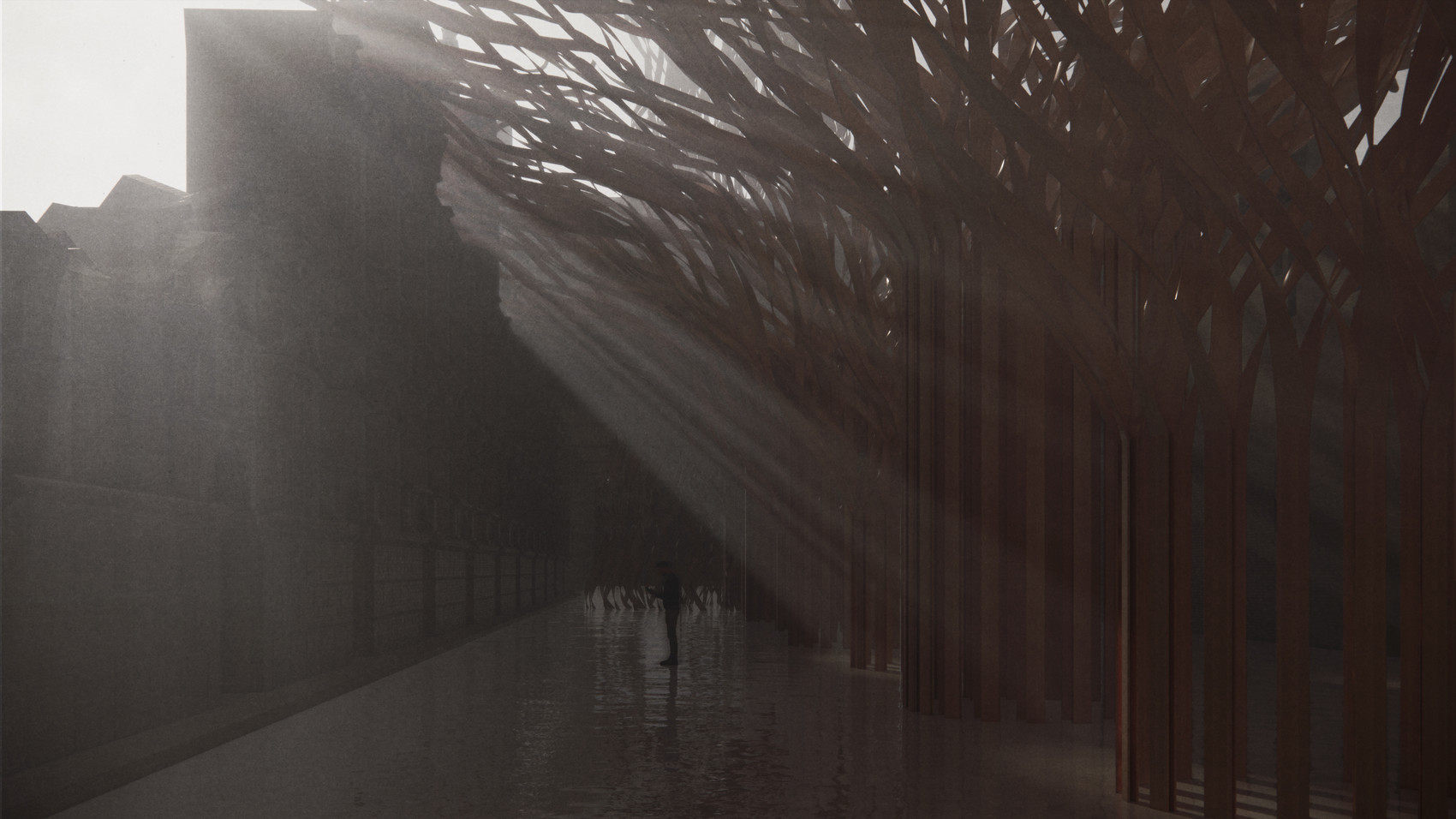

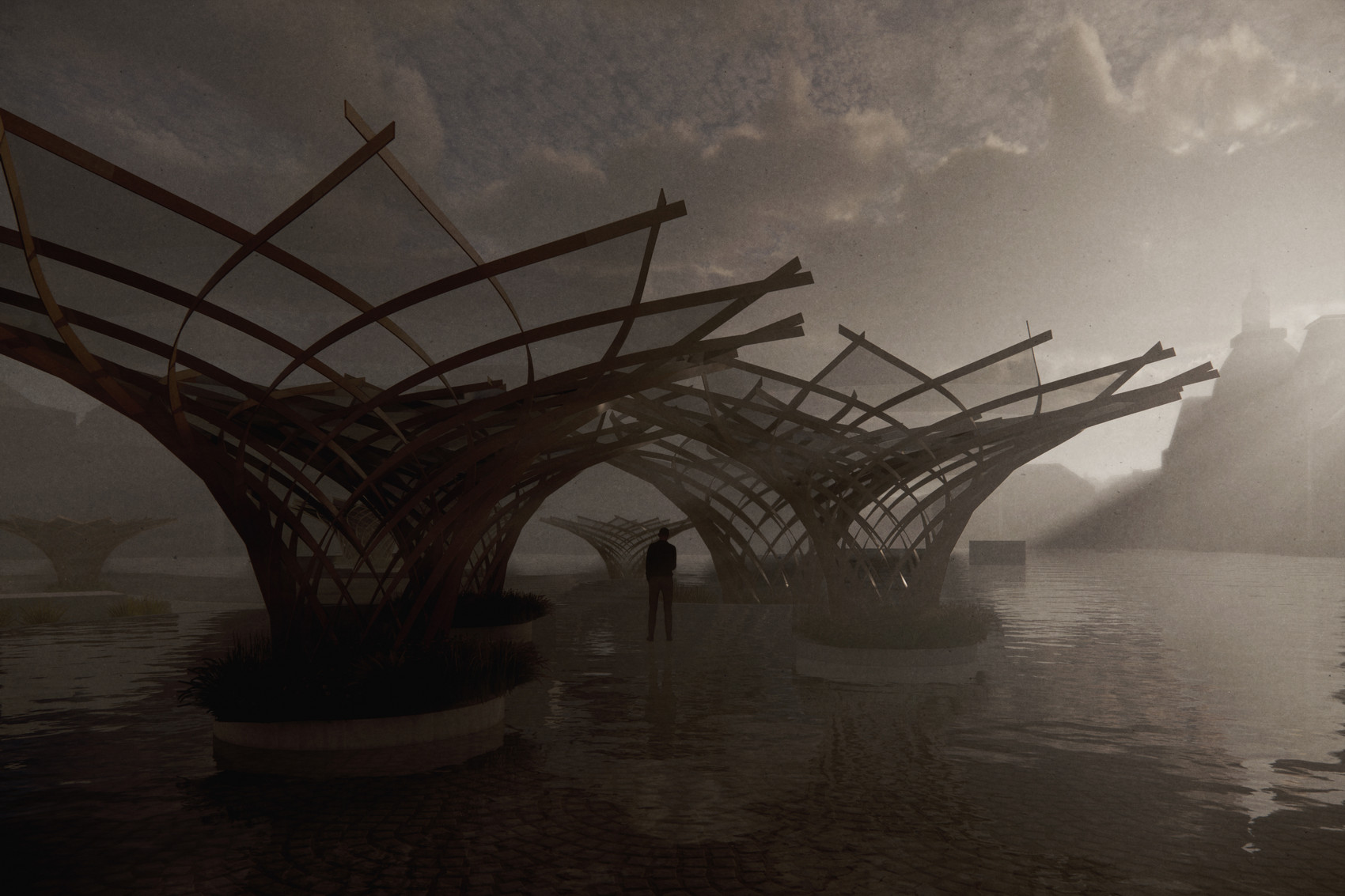

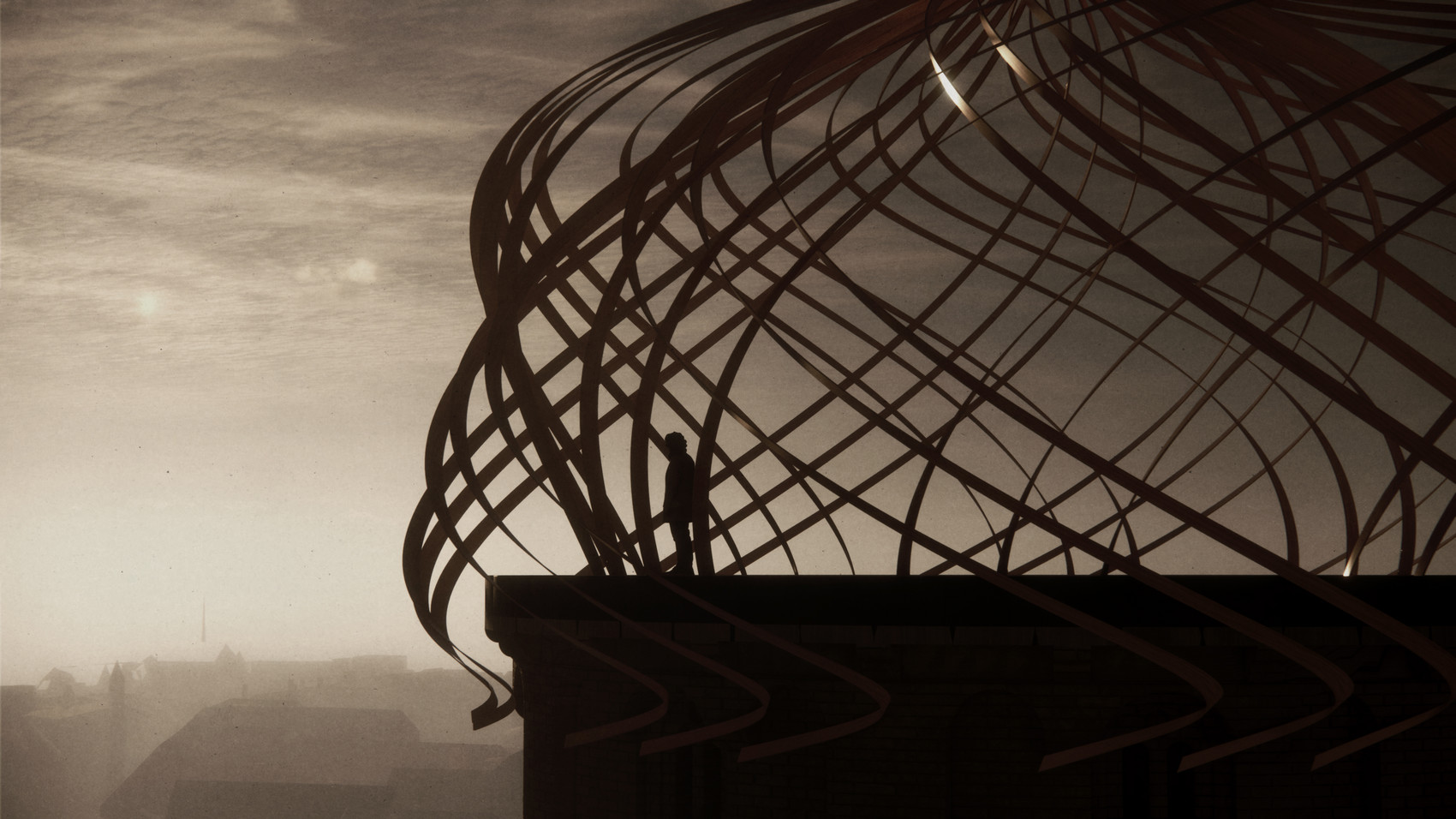

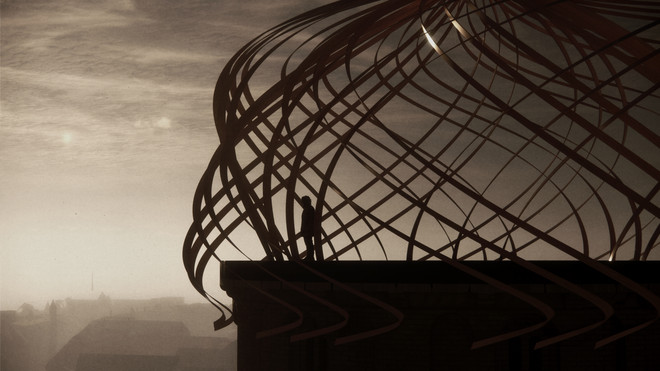

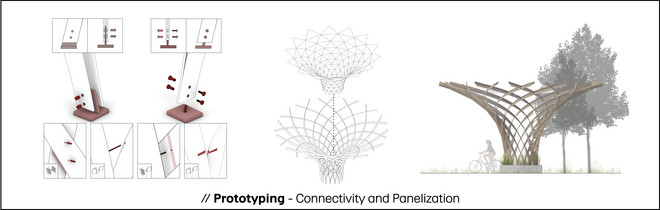

Harmonious Morphogenesis synthesises digital fabrication and traditional timber bending, combining differential-geometric rationalization, with material-information. The result is a computational design framework, generating emergent bent-timber morphologies, allowing for sustainable resource utilization and interactive, material-aware architectural design.

Abstract

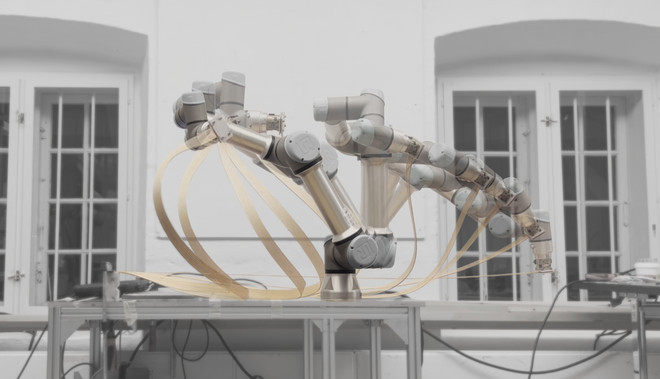

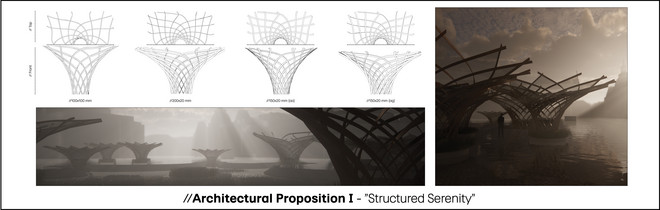

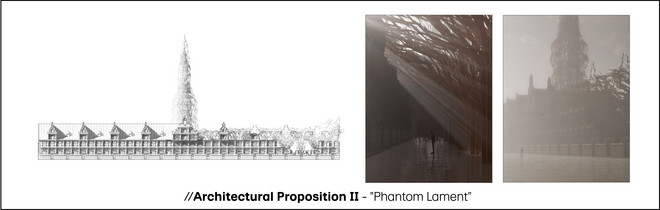

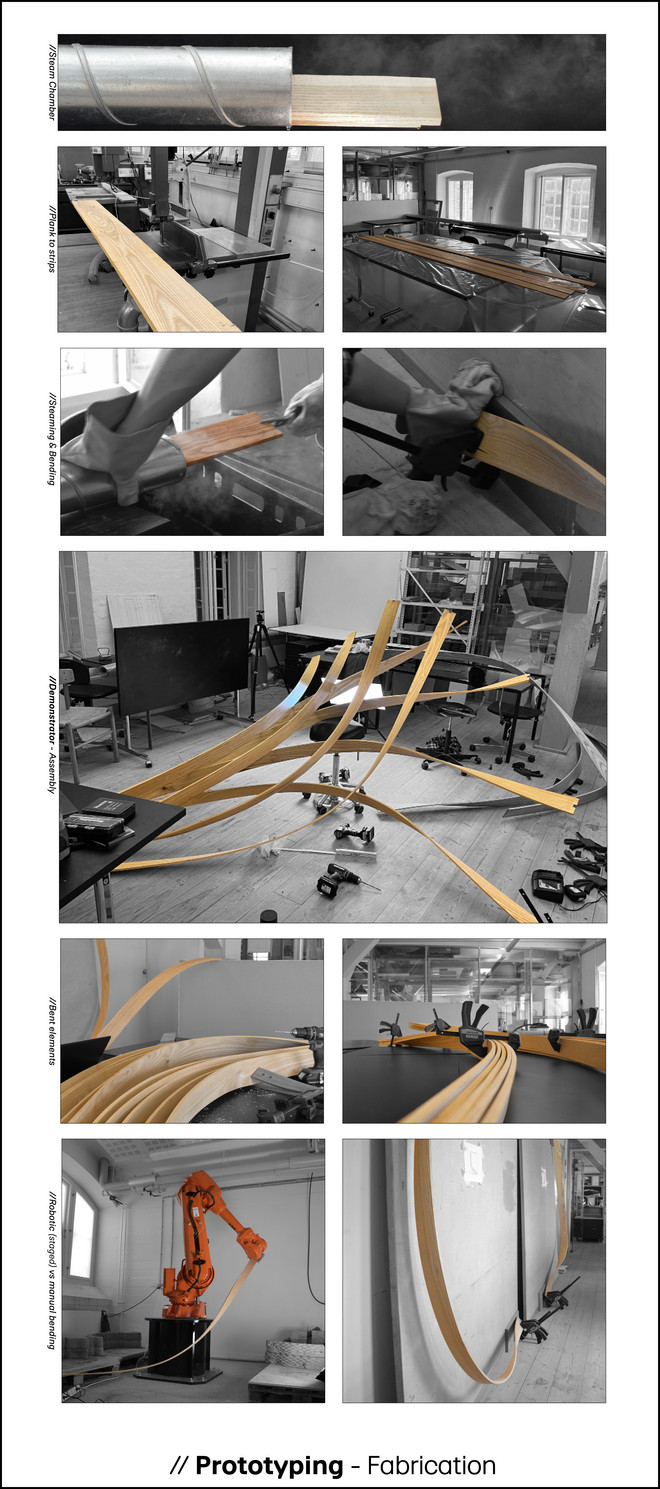

Harmonious Morphogenesis explores the integration of steam bending techniques and differential geometry in digital fabrication processes. The study hypothesizes that this integration can significantly enhance the flexibility and formability of timber, thereby expanding the range of achievable designs and improving sustainability. The paper further investigates the potential of robotic bending to extend this method, allowing for wide geometric architectural possibilities and utilizing the inherent natural behaviour of the material as a design driver. It also discusses the potential for the timber industry to optimize both geometrical capabilities and sustainability conditions, enhancing aesthetic qualities. The research aims to investigate the bending behaviour of timber from various sources, explore the geometric properties related to the bending of plasticized timber, assess the environmental impact of Thermo-Hydro-Mechanical (THM) compared to existing fabrication methods, examine the feasibility of THM as a fabrication method, and evaluate the structural feasibility of plastically deformed timber in curved element systems.

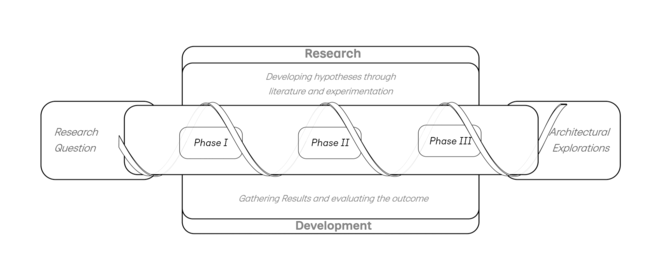

The study employs prospective methods such as surface minimization, asymptotic curves, and sustainability parametrization, and conducts retrospective studies on grading plasticity, digital materiality encoding, material irregularities compensation, bending behaviour prediction, and robotic bending. The research concludes that inherent sustainability, based on material information and sustainable fabrication practice, can be used to optimize early-stage design choices. Through simulation, calculation, and physical testing, a digital model can be created to optimize the steam bending process, limit failure, and enhance architectural exploration.

(From Greek Morphê shape and Genesis creation, literal “the generating of form”) Morphê (shape) Genesis (creation) Harmoniae (agreement, concord) Literal translation; Harmonic generation of form.

Methodology

This interest in designing with the material, lead me to the title of my thesis, but more importantly the philosophical implications of the work I carried out through developing my project.

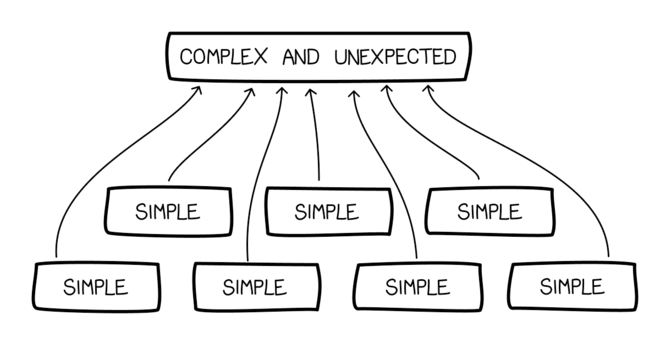

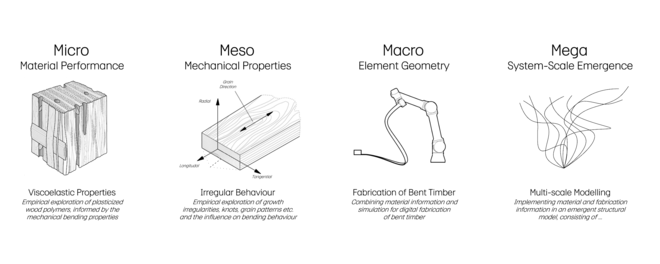

What this means in an epistemological sense is synthesizing single pieces of material and fabrication information, into emergent bending behaviours across multiple scales, in a manner that ensures bending fabricability of elements, as a fundamental nature to the architectural system, where the emergent nature of each bent element, results in complex emergent architectural designs.

“Organic means, in the philosophic sense, “entity”, where the whole is to the part, as the part is to the whole. And where the nature of the material, is the nature of the purpose. The nature of the entire performance becomes a necessity. And out of that comes what significance you can give the building as a creative artist.”

- Frank Lloyd Wright

Research Question:

“How can the bending behaviour of timber, be rationalized and integrated with material and fabrication information, into a generative architectural modelling framework?”

Objectives:

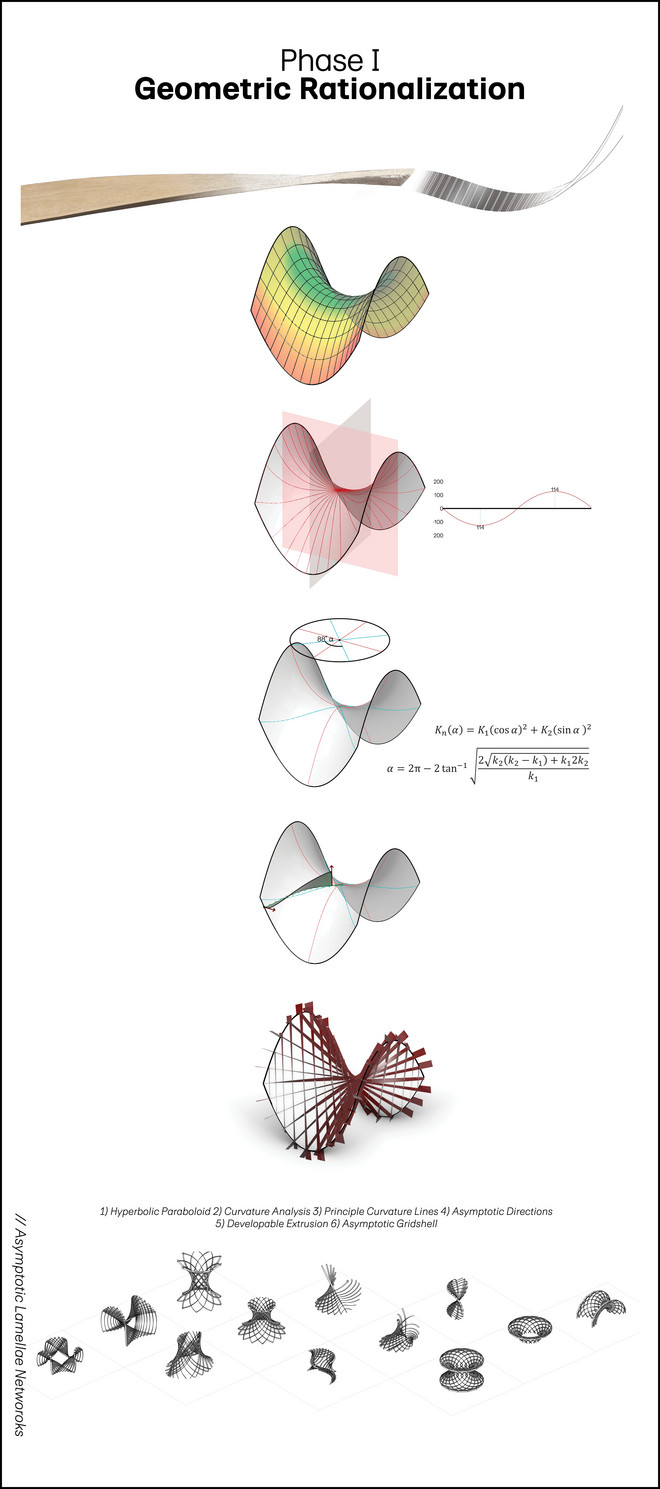

I. Develop a computational model to generate and rationalize fabricable geometries of bent timber strips by explaining their geometric properties.

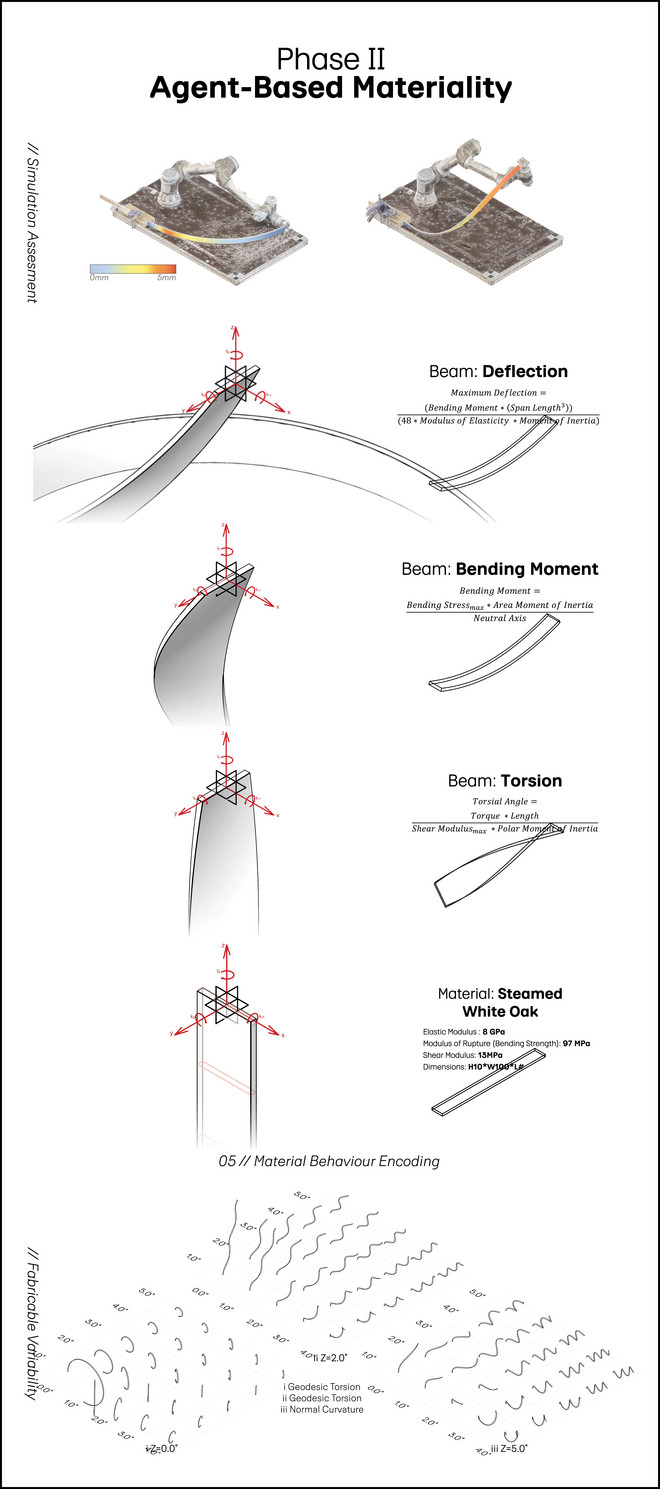

II. Develop a computational method for simulating geometries that incorporates material and fabrication information by assigning specific properties to geometric objects.

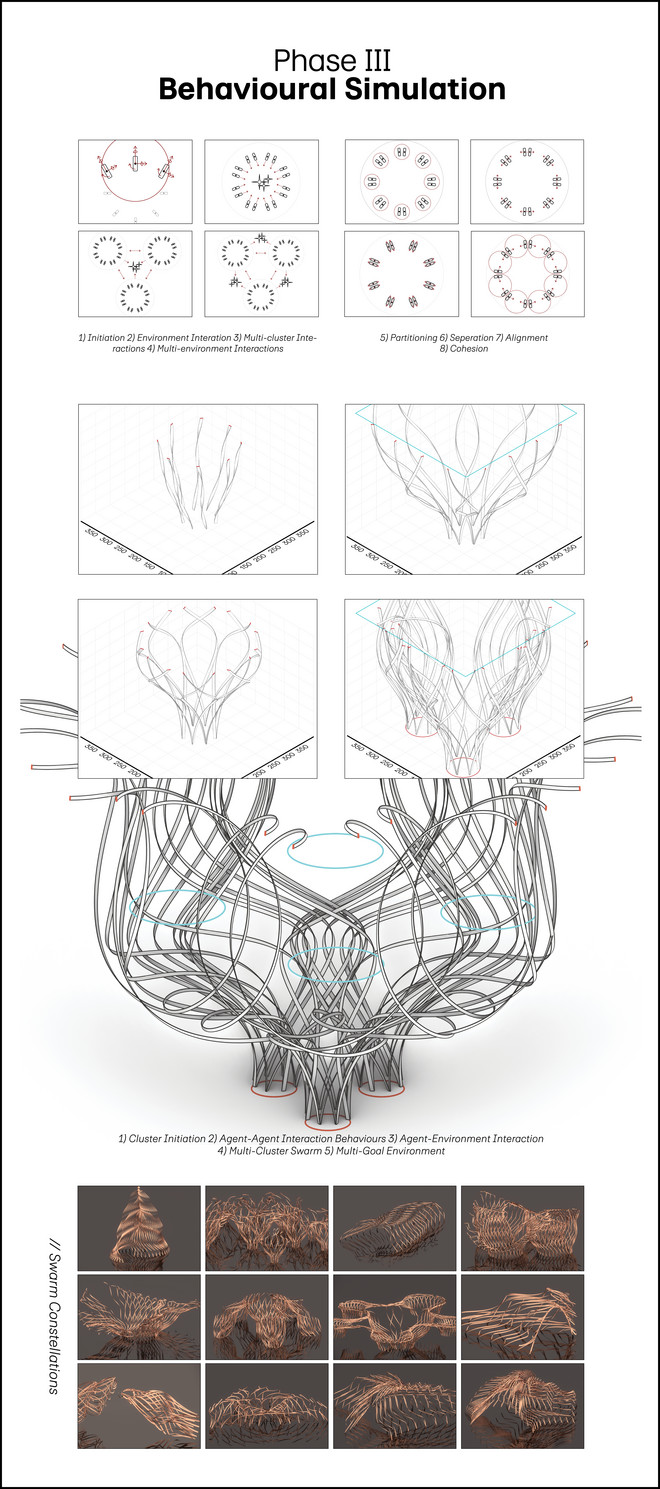

III. Model the emergence and simulate the complex behaviors of multiple elements in coherent architectural systems.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål