.

Project description

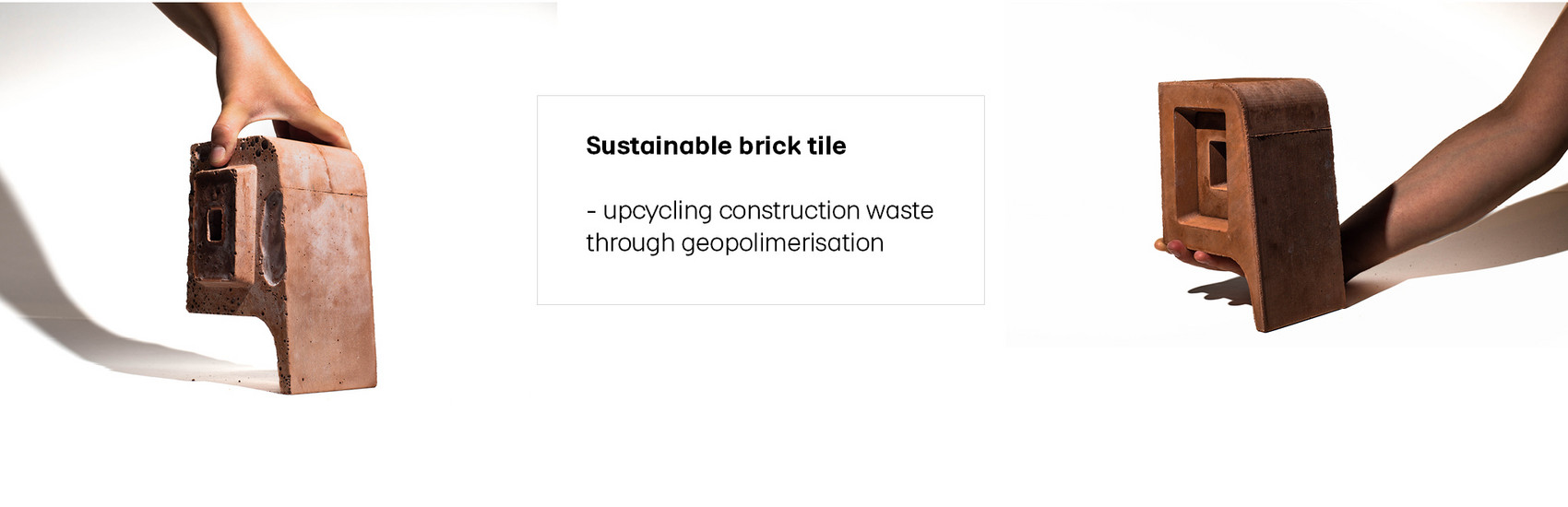

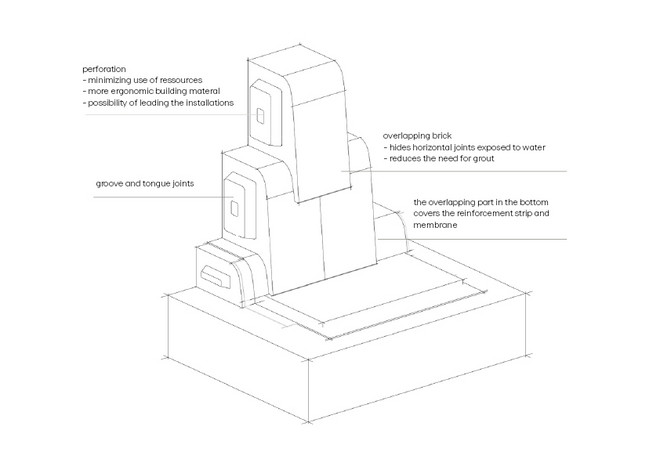

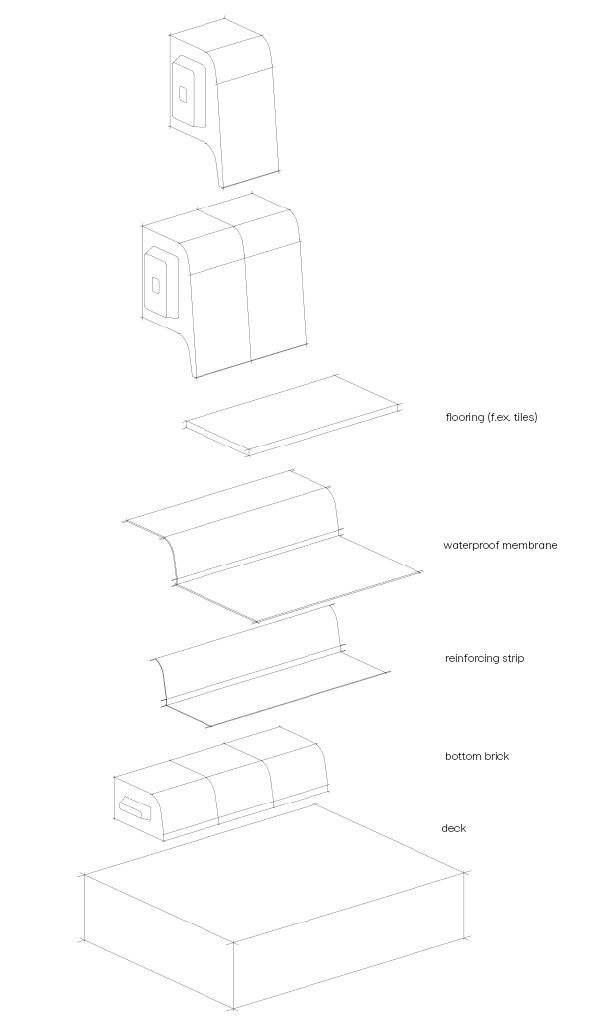

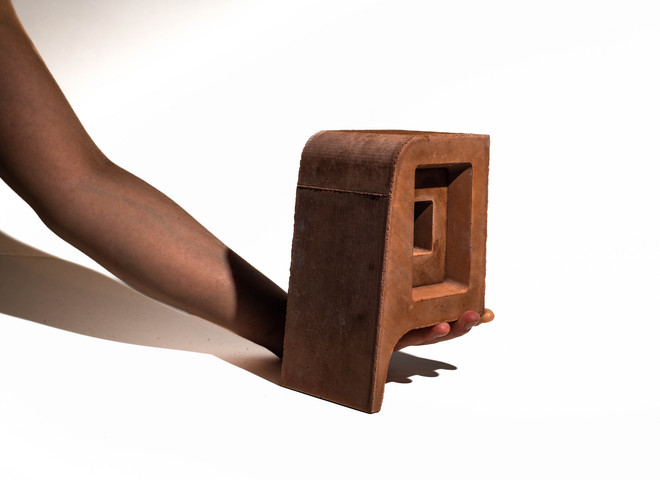

Through a series of experiments and multiple production methods, the project aims at optimizing geometry and manufacturing of bricks with use of reclaimed construction waste such as crushed bricks as well as by-products such as fly ash and ground granulated blast furnace slag. The new sustainable joint-free brick design introduces ambient-cured bathroom wall system, providing both a brick, a tile and a waterproofing in one, hence the name – brick tile.

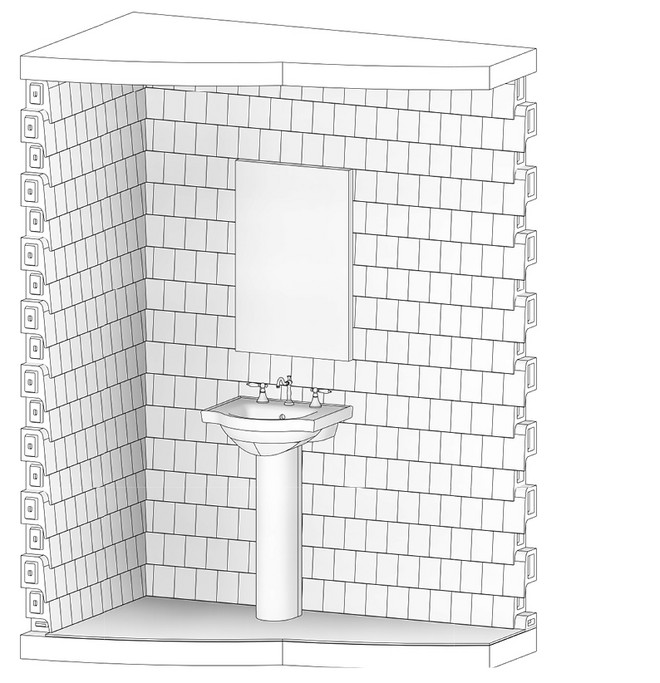

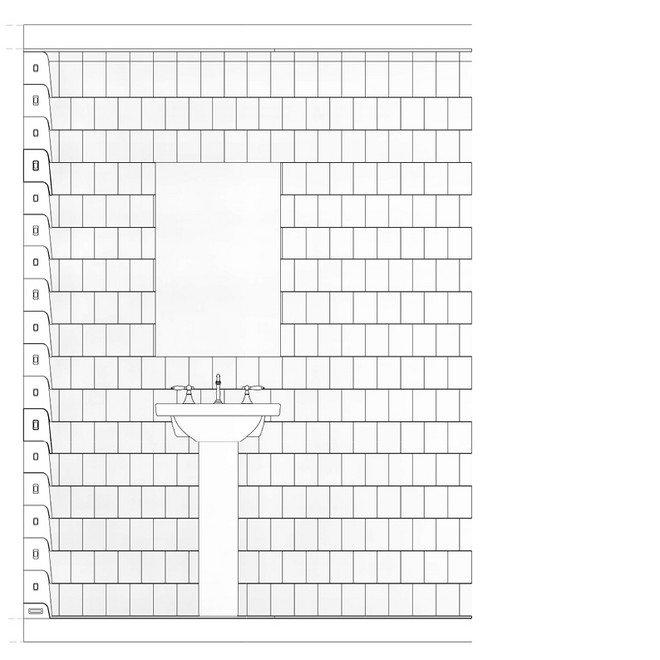

BUILDING SYSTEM AND DESIGN OF GEOPOLYMER BRICK TILE

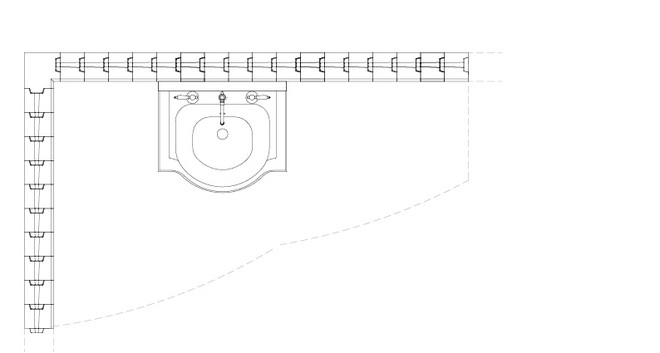

Bathroom constructed with geopolymer brick tile

Floor-wall junction detail

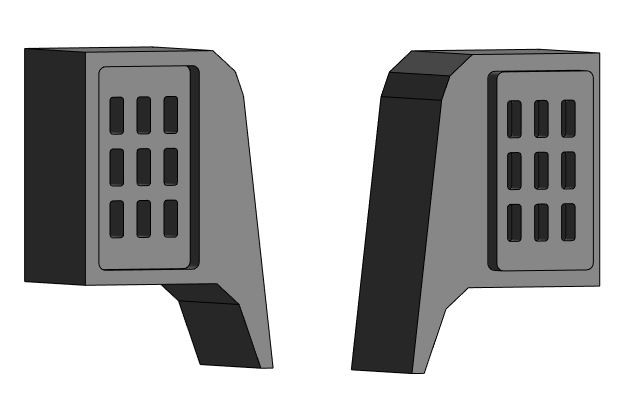

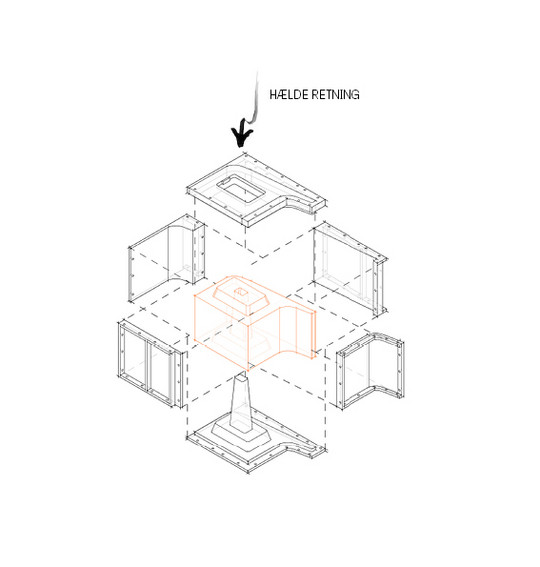

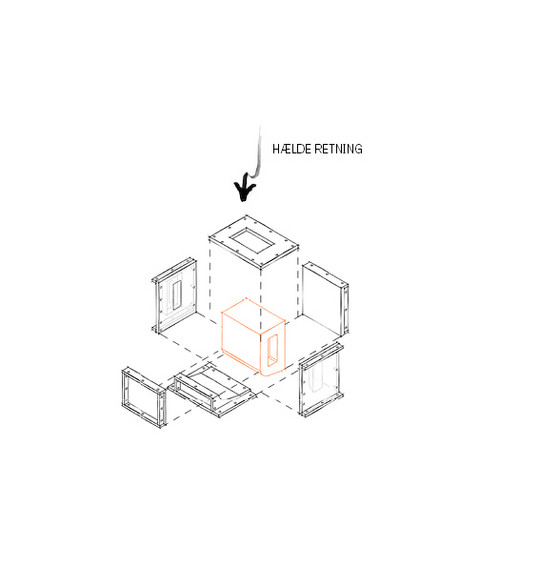

Introduction of two brick modules

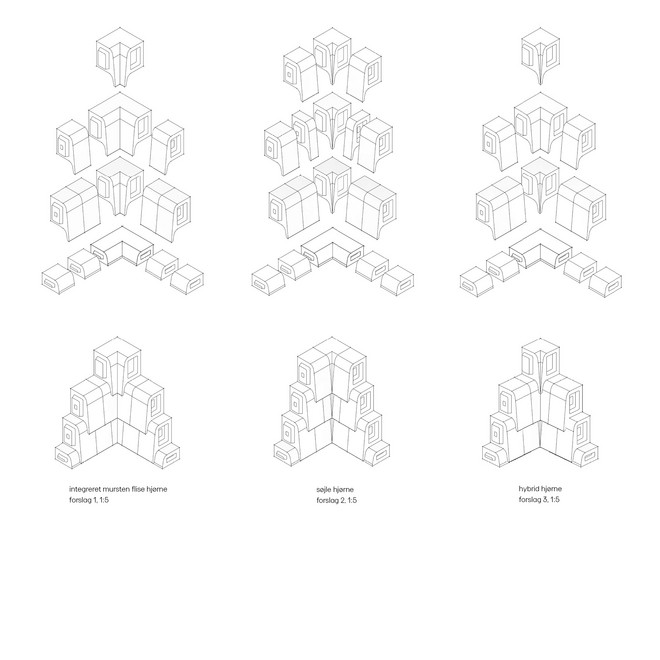

Corner buildup - three iterations

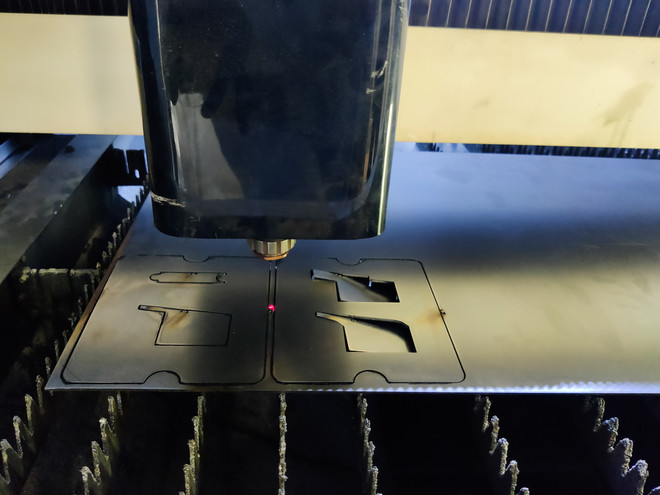

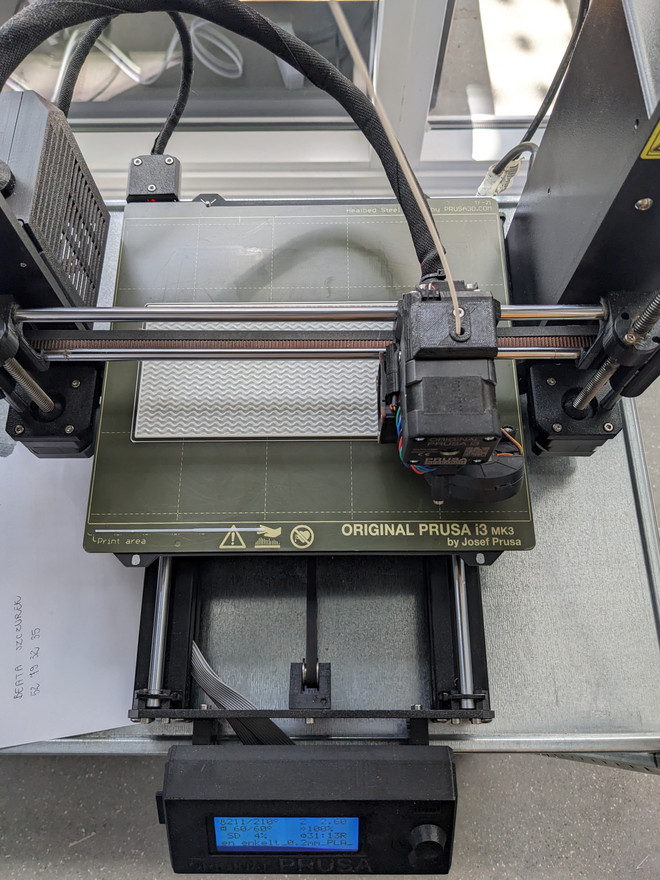

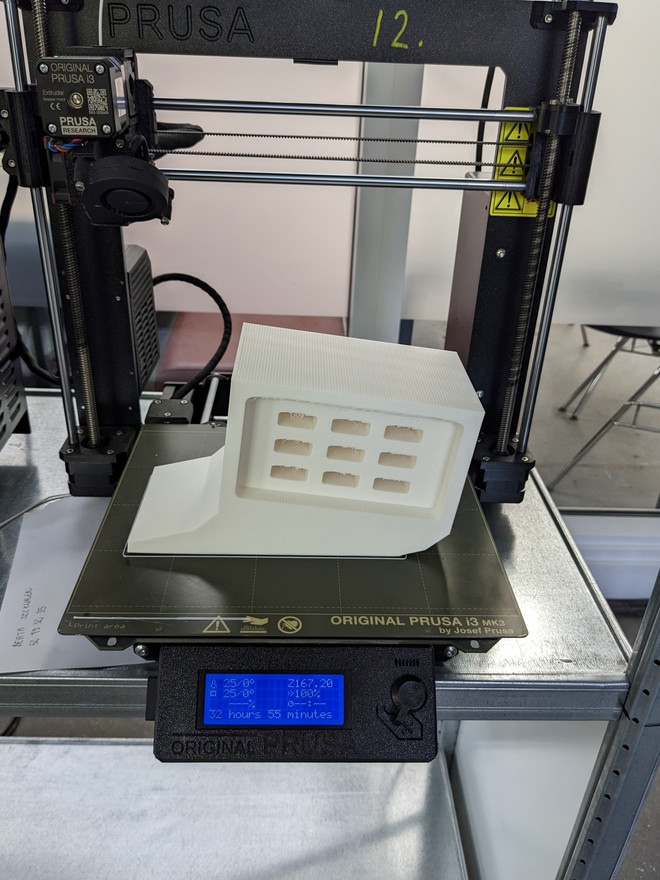

Geopolymer brick tile production

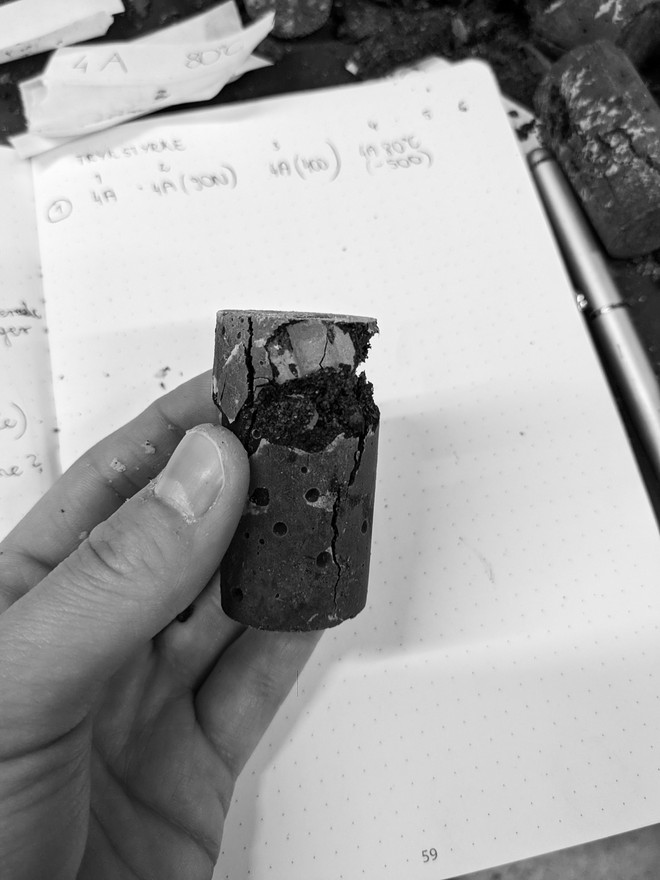

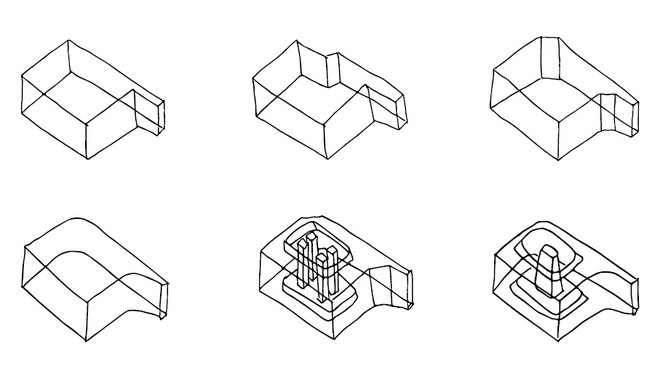

Foto documentation of design development process

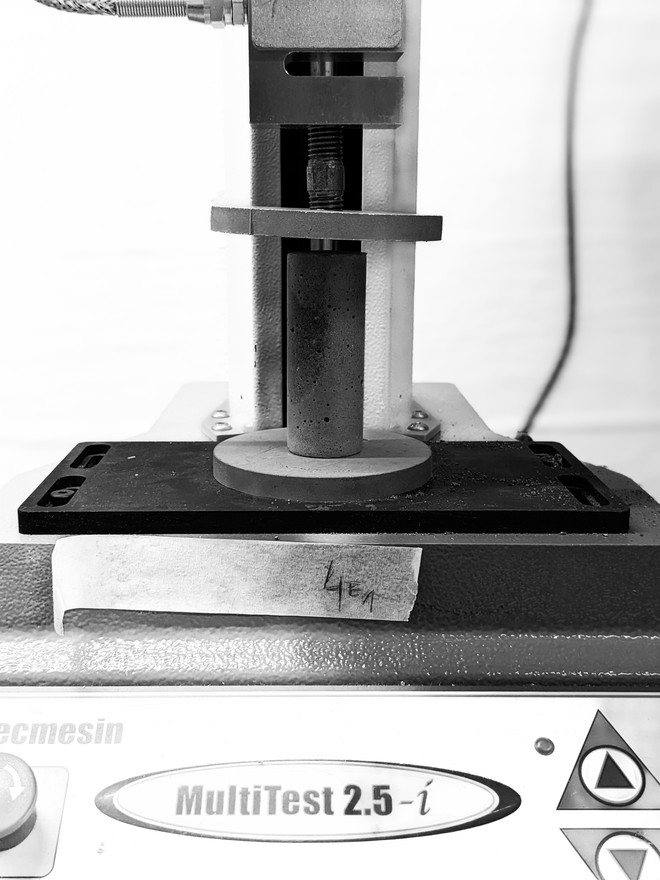

GEOPOLYMER EXPERIMENTS

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål