Thermal [Mass] Customisation

Thermal [mass] Customisation

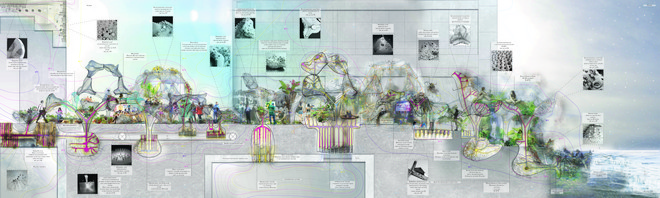

Speculative exploration into designing with material energies

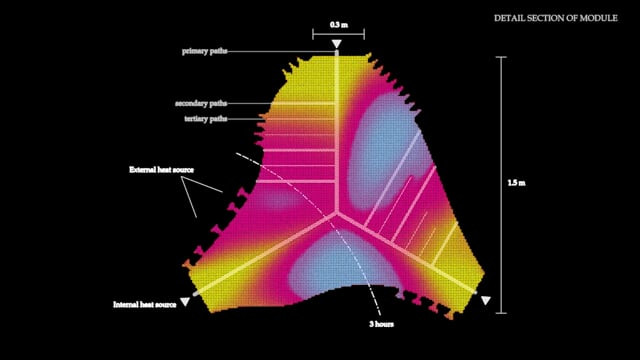

- This research aims to question how thermal energy is conceived and controlled within architecture.

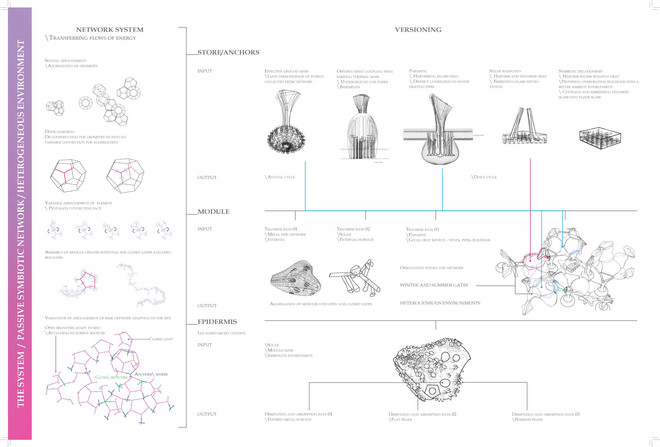

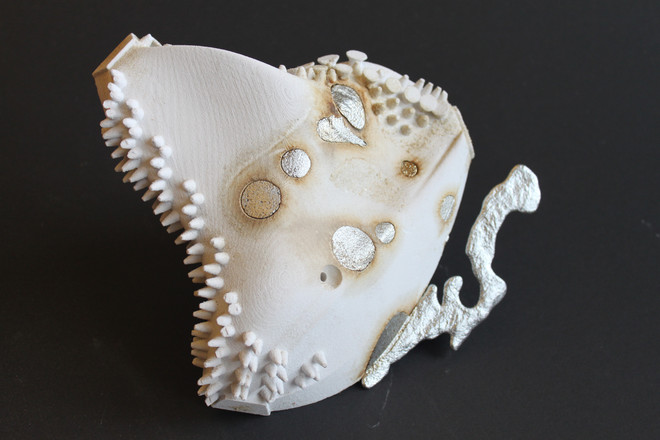

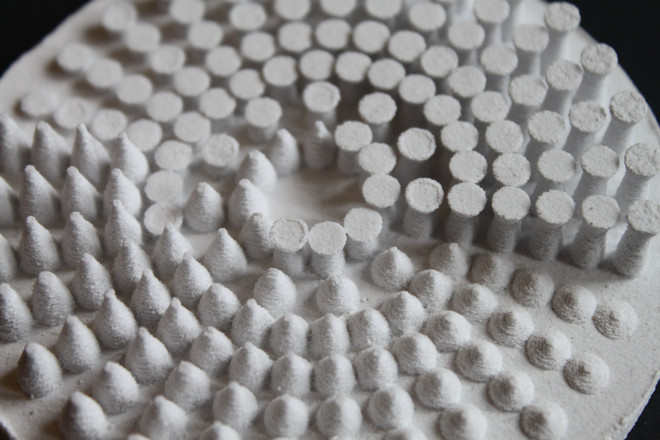

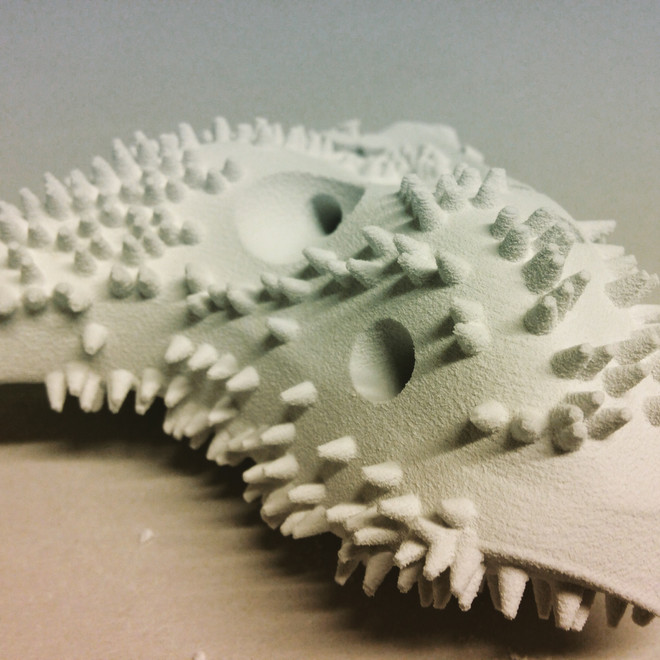

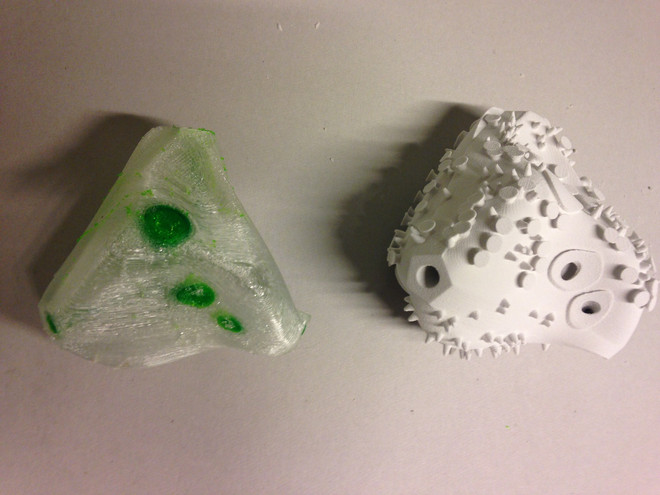

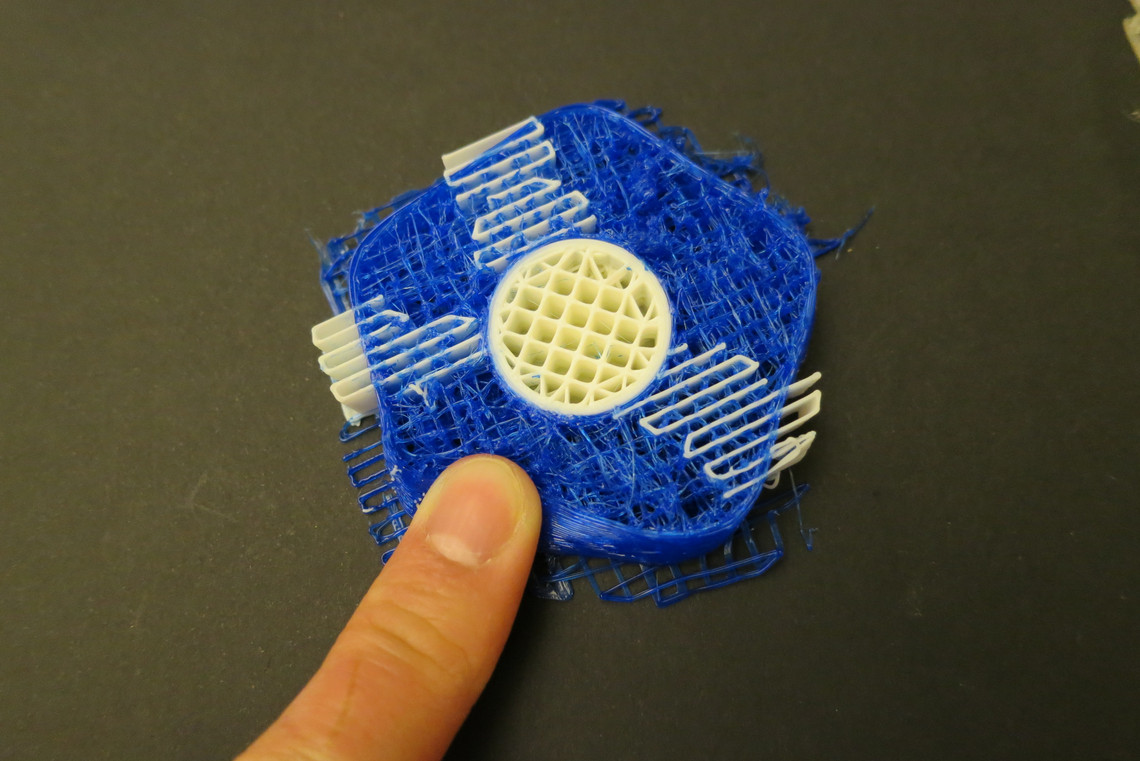

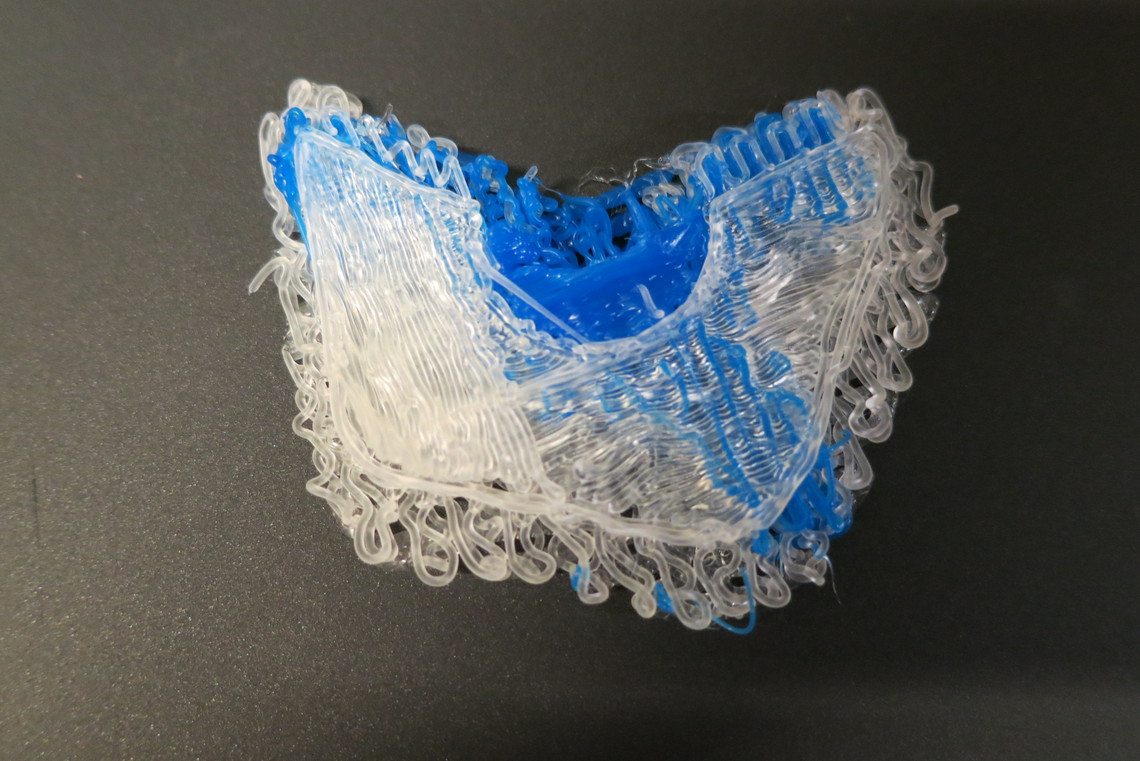

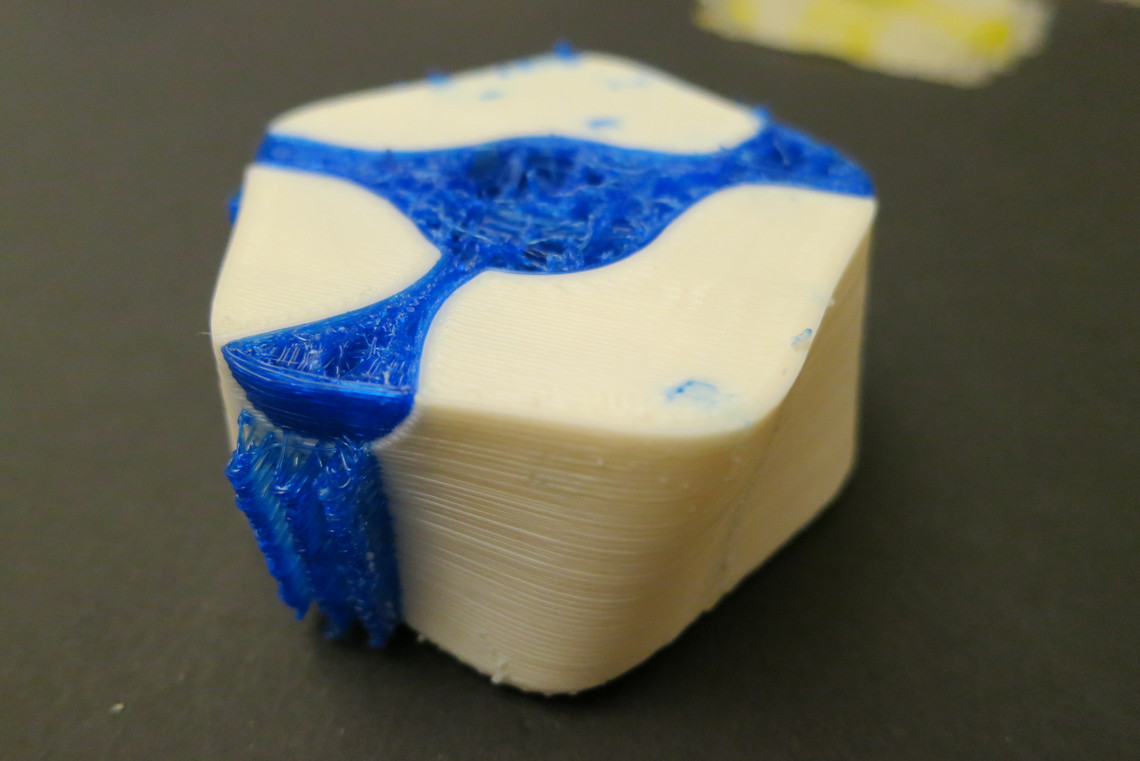

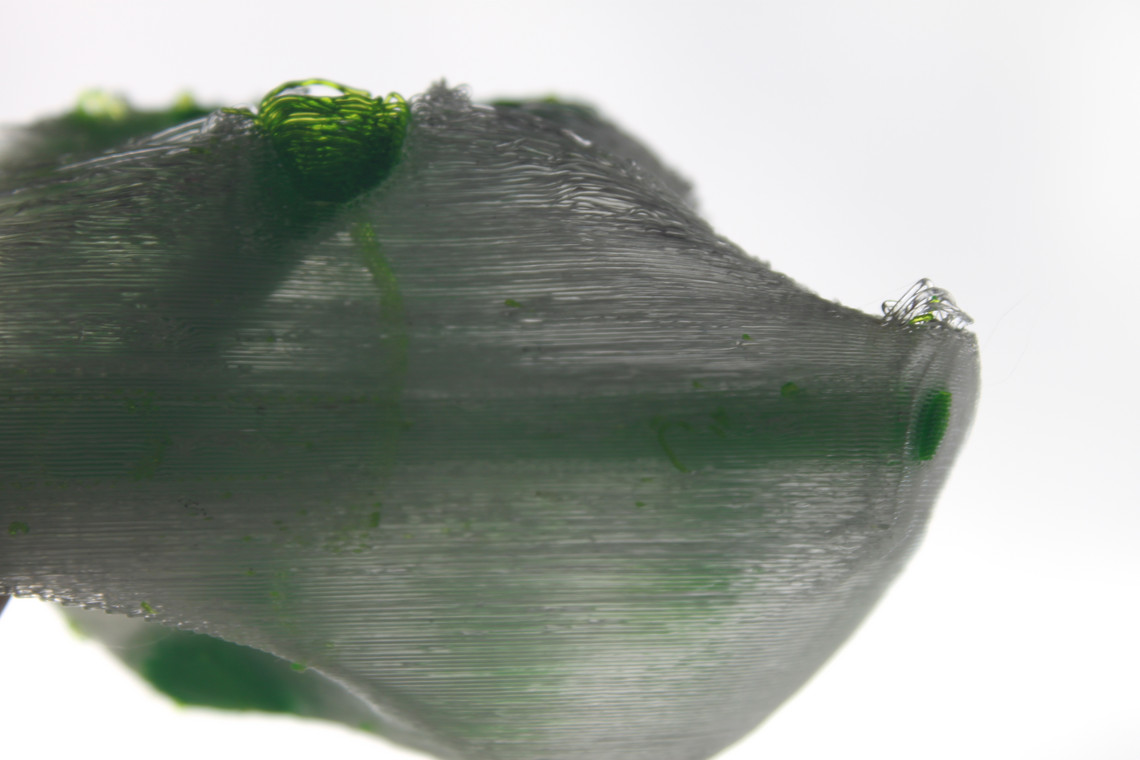

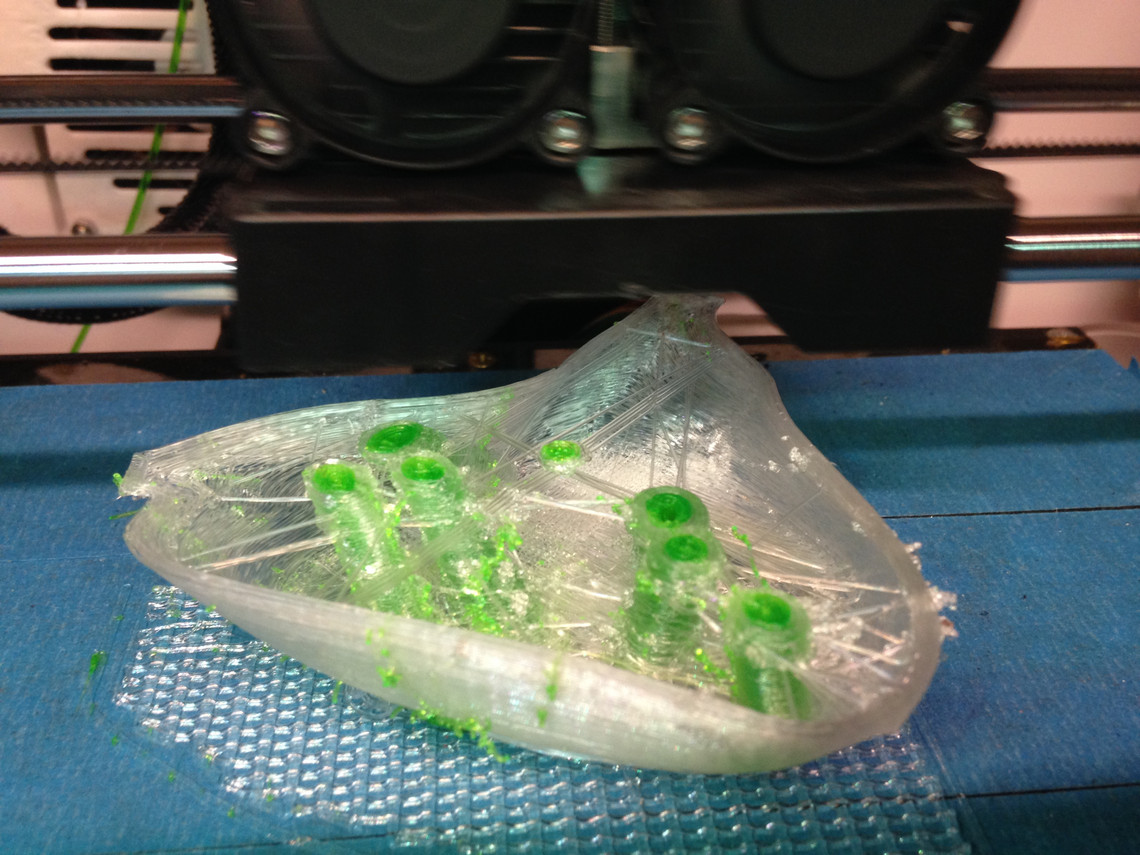

- It develops and explores designing a system of elements and their fabrication process.

- The research uses the latest technology from FLIR for critical analysis.

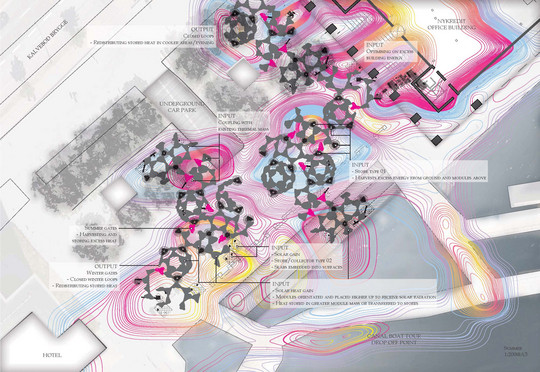

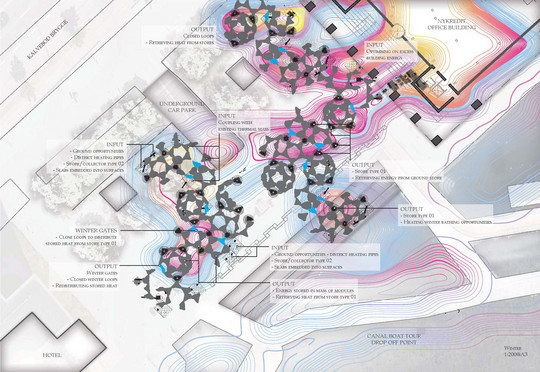

Observing the environment, it is evident that we operate in a nonuniform manor, yet we often design using standards and averages. Current approaches to thermal control empahise standard range of values; however these can only ever be averages. My research aims to envisage and prototype an alternative architectural application for understanding thermal mass.

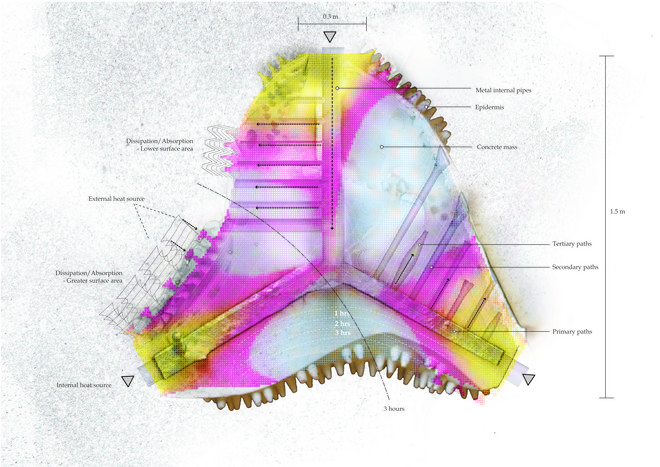

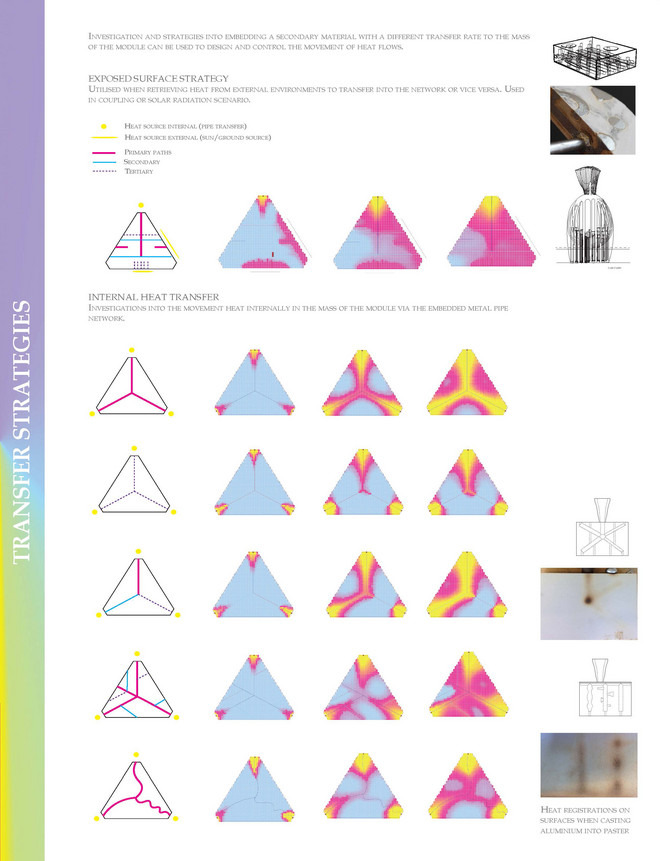

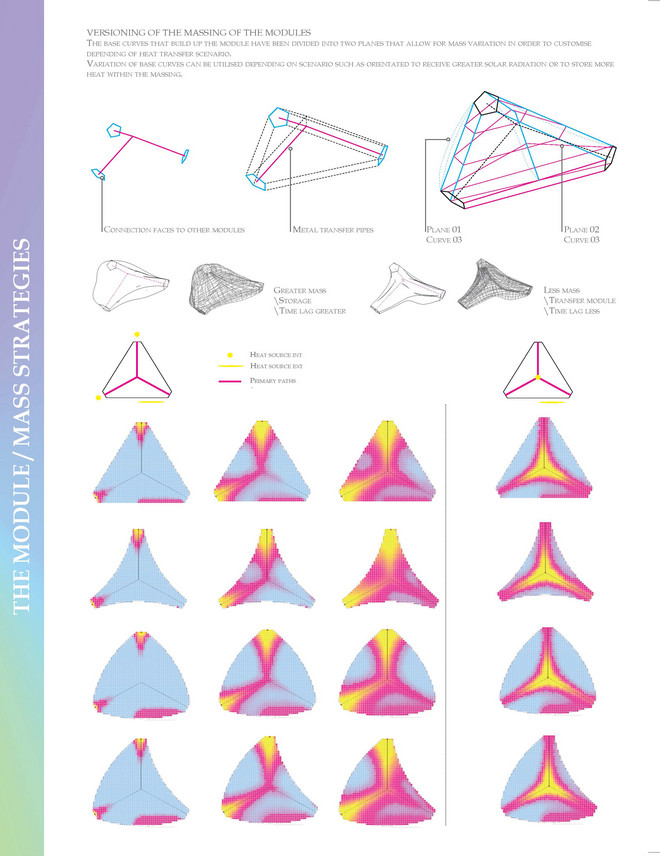

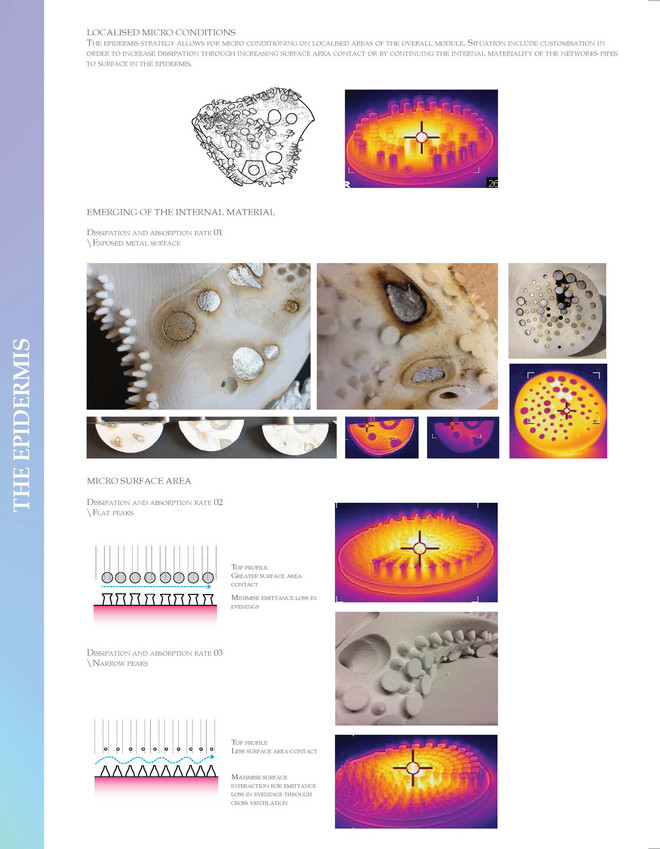

Within this framework and through the application of thermal mass; the interest departs from the ability for materials to absorb and release energy at different rates. This notion builds on the engagement with the opportunity to create a heterogeneous ecology of environments which can steer or prolong activities in the public realm. The understanding and reinterpretation of thermal transfer, sourcing energy and distribution rates drives the investigation into the symbiotic and parasitic opportunities that can be utilised in our built environment.

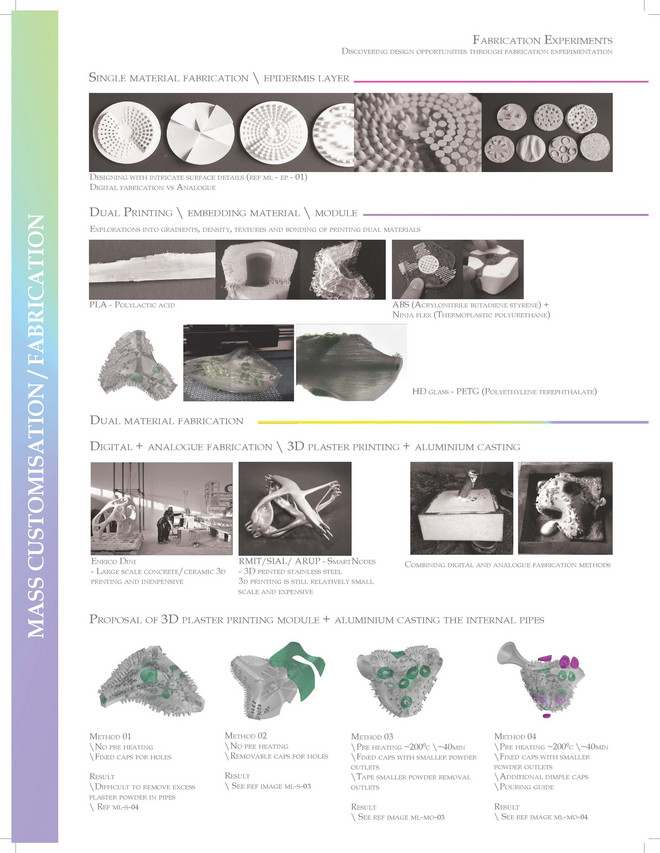

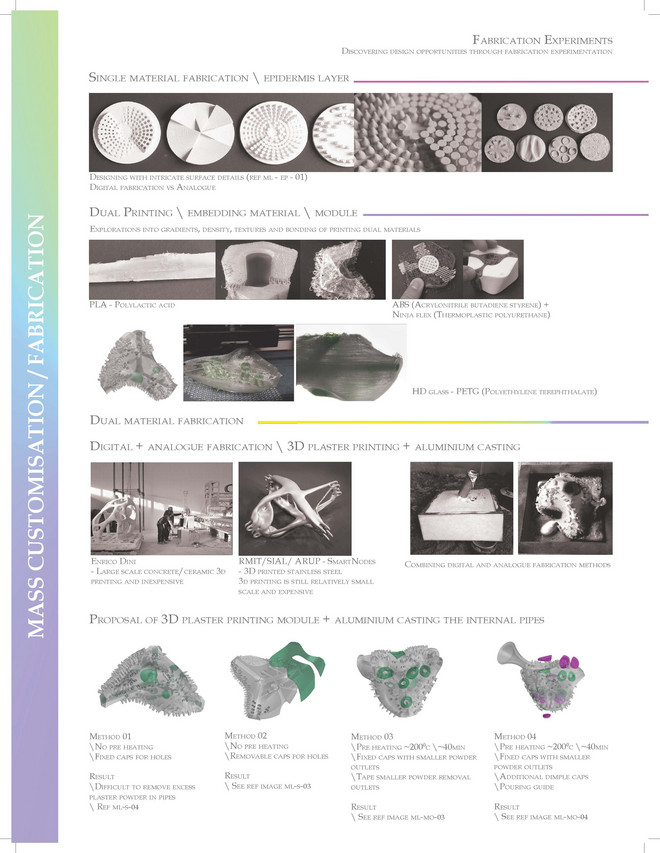

Investigating designing through the methodology of developing a systems logic and fabrication processes; the attitude towards designing for mass customization and ‘versioning’ will be explored.