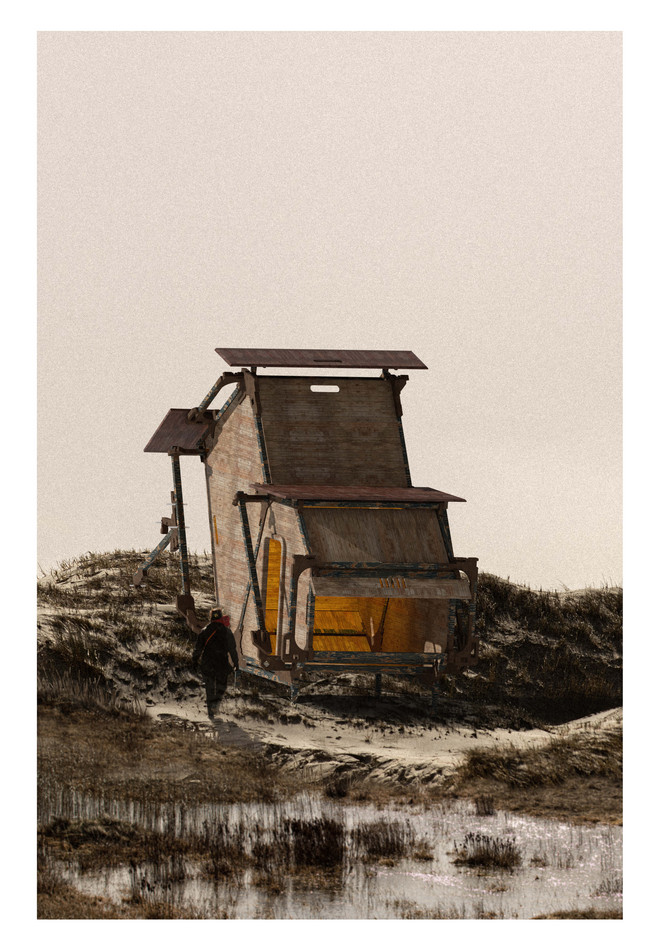

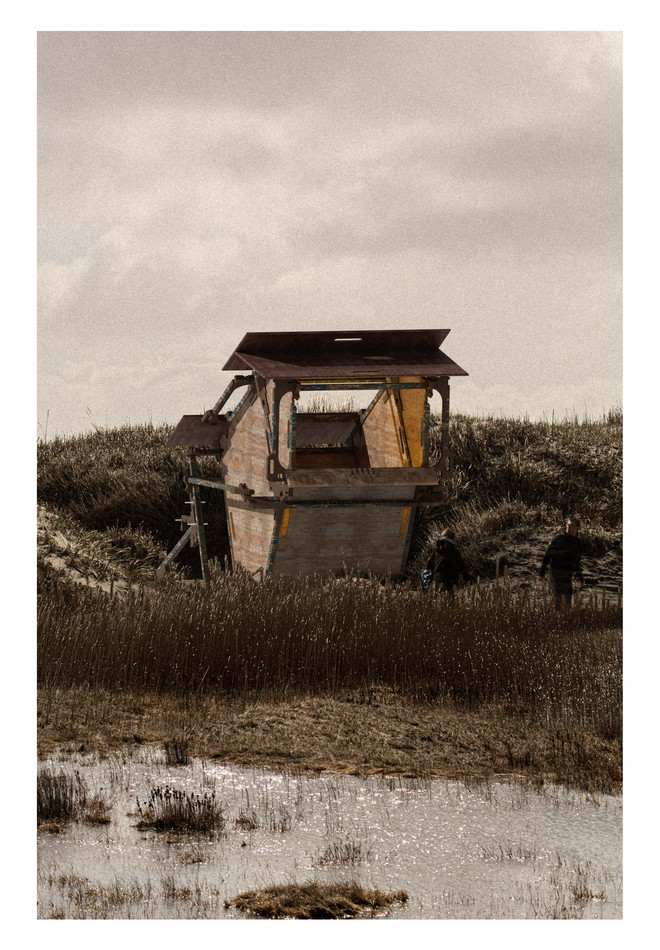

Buildings of Theseus

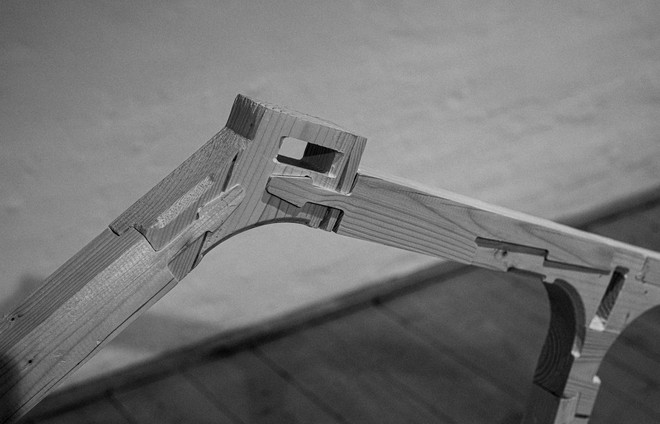

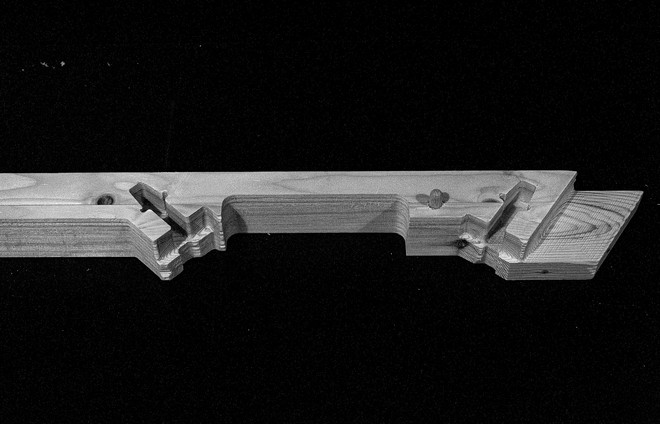

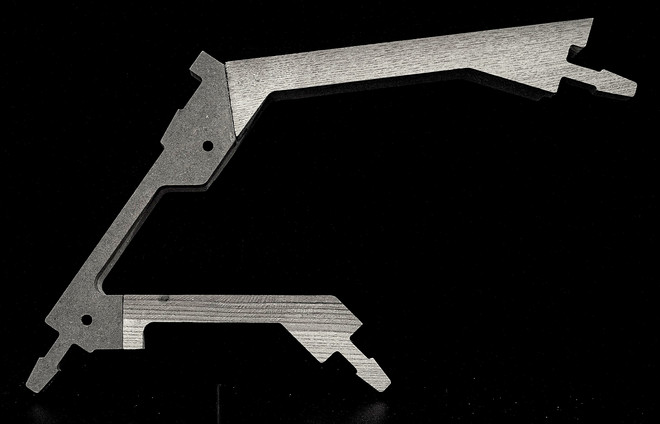

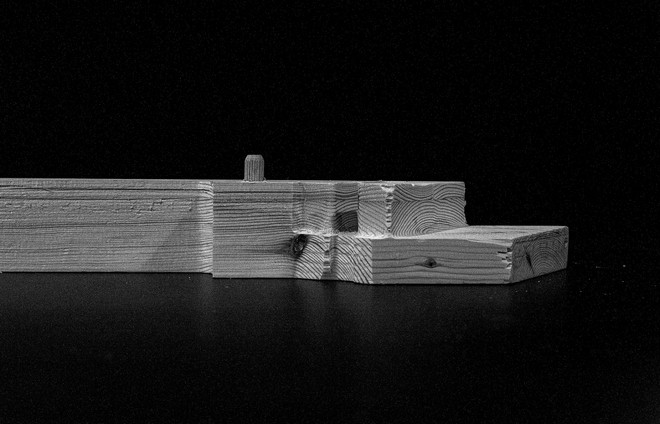

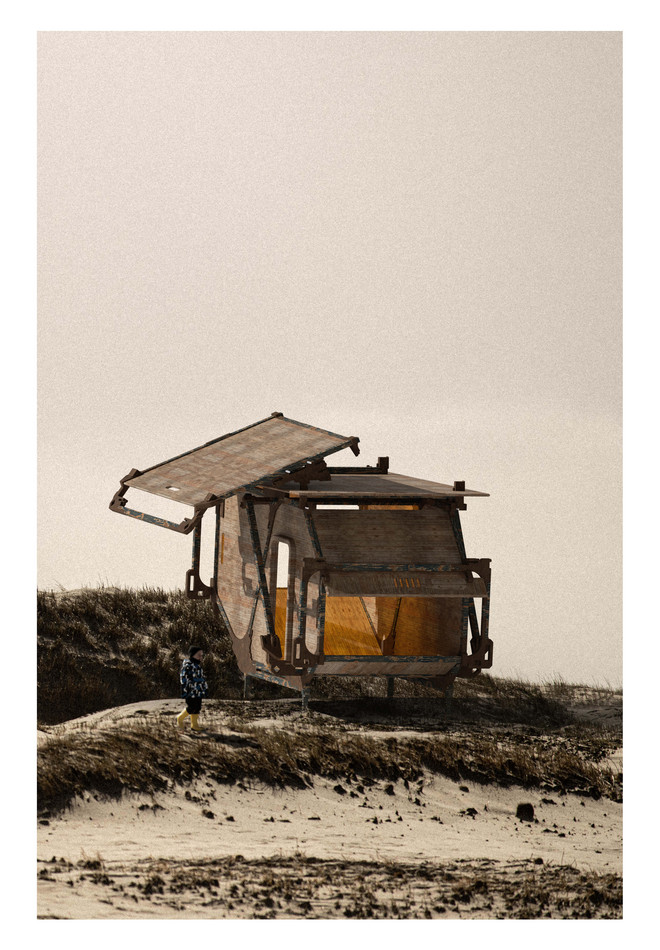

The research described in this dissertation explores a novel computational design method for the multiple reconfiguration of timber structures to extend its material life cycle. The construction sector produces 37% share of global CO2 emissions. With the growing concern for the impact the built industry has on the environment, we need to re-evaluate our architectural practices by looking at the life cycles of our materials and how they can be reused. Timber offers the possibility to reduce the sector’s carbon footprint as it is a renewable resource. Modern timber construction has already been highly integrated with automation and prefabrication (Construction 4.0) which could potentially increase the viability of timber disassembly. The benefits of using timber joints without nails allow the structure to be assembled and disassembled in a different site, context, and time. Traditional joints, however, pose two main challenges for automation of assembly. Firstly, traditional joints must be precise for it to function and fit well. Secondly, the aforementioned tightly fit joints require large frictional forces to be overcome during insertion. I will investigate how computation can prolong the life cycle of timber structures by designing for multiple stages of reconfiguration. This research project would also address the current limitations of designing for disassembly. With the utilisation of computation it would expand the potential of timber assemblies and speed up its adoption in the construction industry. The proposed process targets factory based prefabrication and robotic assembly of bespoke timber elements with modular joints. The key research objectives are: (1) explore the use of computer vision, CNC and automation to track, evaluate and machine timber elements to prolong its material life cycle; (2) explore timber joints that are adapted to automated fabrication, reconfigurable and multi-functional.

Keywords: disassembly – timber joints -

prefabrication - life cycle

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål