Bio-Plextiles

[[{"fid":"356935","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

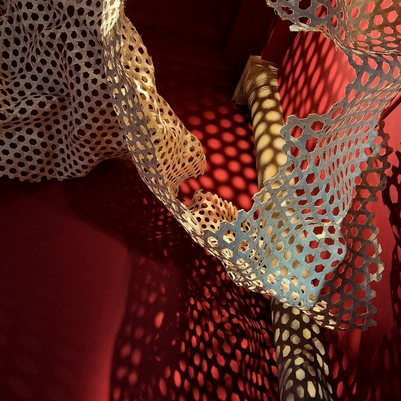

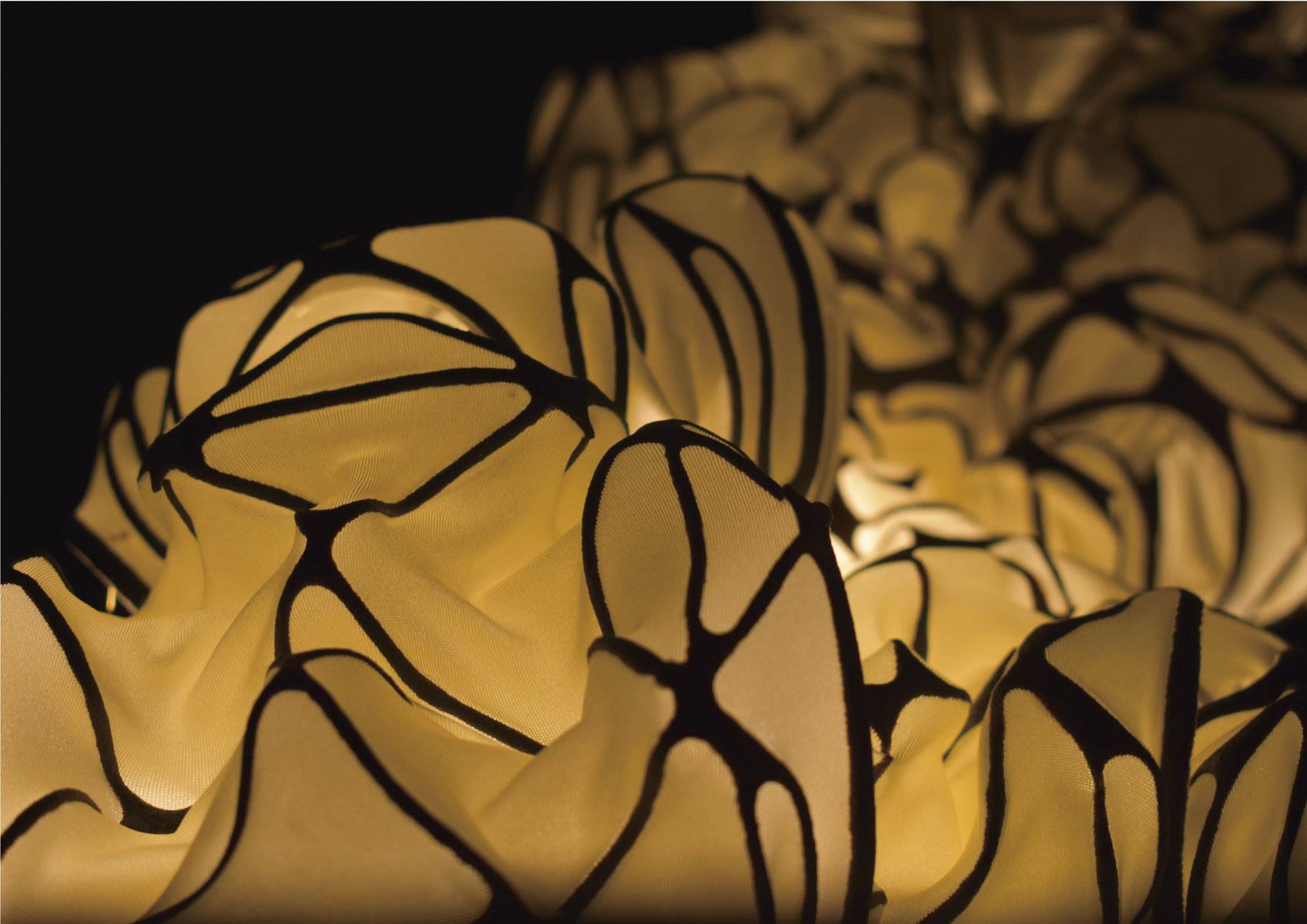

The research proposes a material study to create a composite created from the combination of a bioplastic, which fulfils the necessary parameters for Additive Manufacturing, and a textile membrane that can achieve a desired adhesion to the print and perform as expected and simulated. It speculates about the architectural potential of the composite system through a series of physical prototypes.

[[{"fid":"356936","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

[[{"fid":"356937","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

Material Exploration

Initial exploration to choose the proper materials to create a composite consisted in determining the necessary parameters for each material.

[[{"fid":"356958","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

For bioplastics , 7 different recipes were tested, mixing different ratios of a solvent + biopolymer + plasticizer +additive (if desired). For these tests, water and vinegar were used as solvents, gelatin and cornstarch as biopolymers, glycerin as plasticizer and seagrass and eggshell (in powder) as additives.

[[{"fid":"356963","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

For the textile membrane , 4 types were assessed: 2 different polyester meshes, viscose textile and lycra.

[[{"fid":"356967","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

The chosen materials to create the material composite are:

- Bioplastic formula: 82% water + 8% gelatin + 5% glycerin + 5% seagrass

- Textile membrane: Lycra (80% polyester 20% elastane)

[[{"fid":"356971","view_mode":"top","fields":{"format":"top","field_file_image_alt_text[und][0][value]":"","field_file_image_title_text[und][0][value]":""},"type":"media","attributes":{"class":"media-element file-top"}}]]

The composite created has the possibility to be re-melted, to separate materials and re use each element separately.

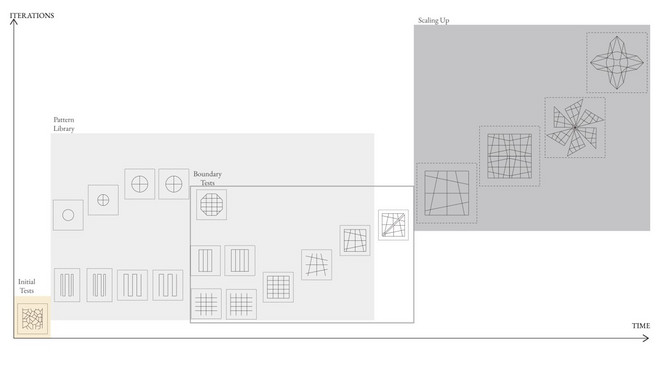

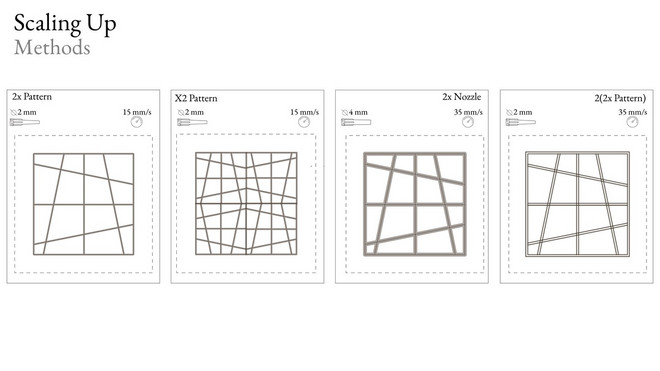

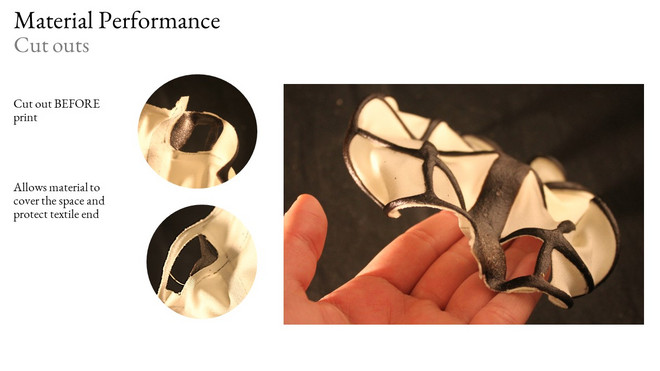

Pattern Library

Different geometrical patterns were tested to observe and understand the performance of the different materials working together. Different characteristics were introduced over time, such as boundary conditions, irregular grids and scaling up.

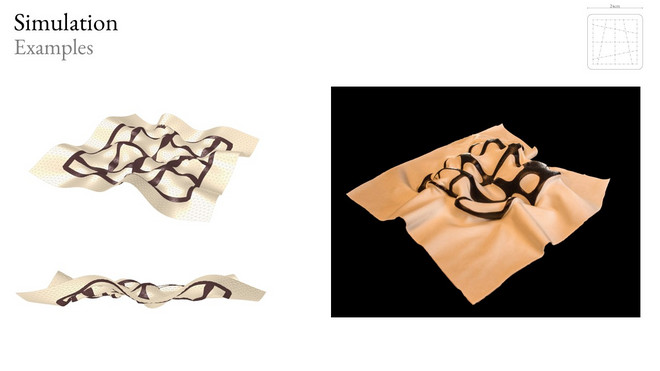

Simulation

While working with a bio-material with a high level of unpredictability made having a digital simulation was used to understand and help with the prediction of new and different patterns without having to create the physical prototypes.

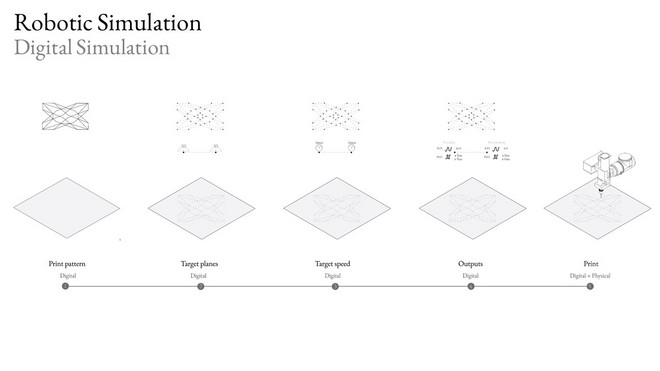

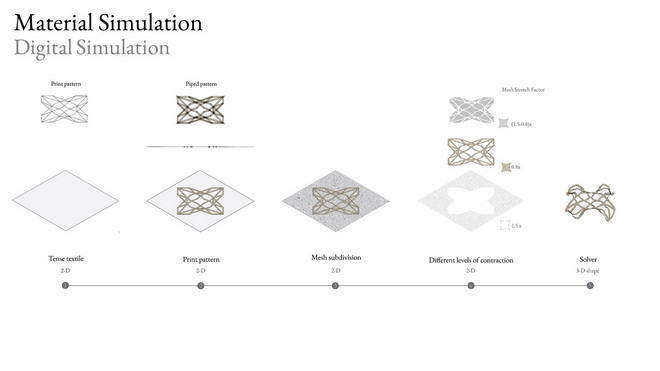

Three different types of simulations were used:

- Robotic Simulation, used not only to visualize the robot path before running it but to set up the different speeds and to control the flow of the material by controlling an analog output and activate the retraction if needed to achieve a cleaner print.

- Material Simulation, created with a dynamic relaxation where the meshes were given different levels of contractions as the physical materials had. The textile mesh has assigned a 1.5 factor, the print mesh has assigned a 0.8 factor and the textile islands meshes have the result of the subtraction of those 2 previous factors (1.5-0.8=0.7 factor).

- Material’s Intervention Simulation, replicates the intervention created on the prototypes to join the sides and create the spatial components used for aggregation.

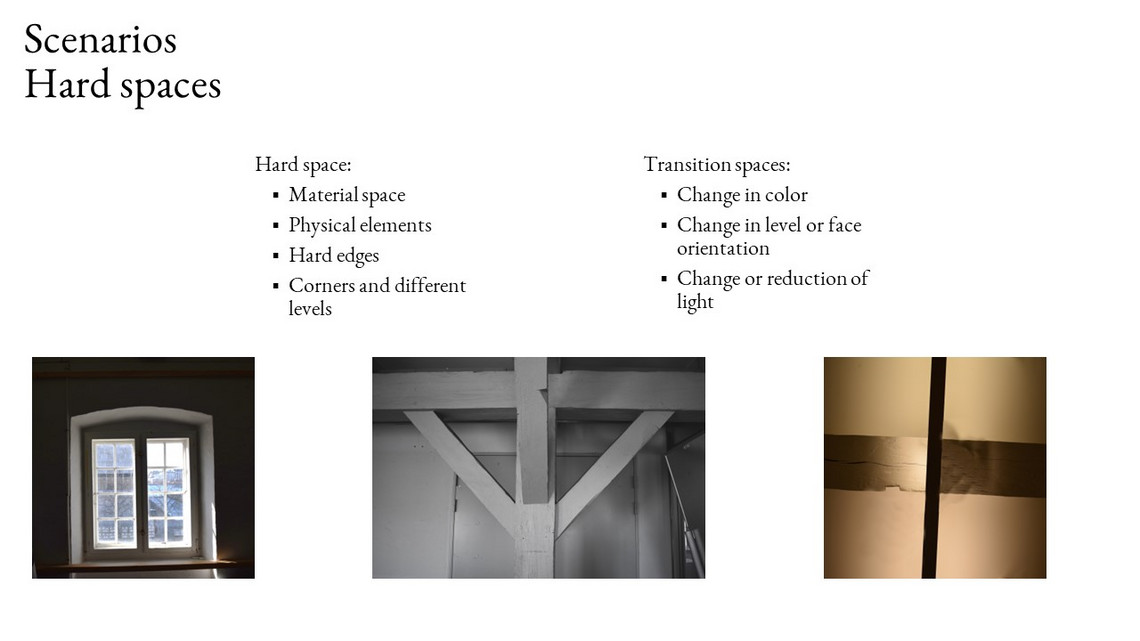

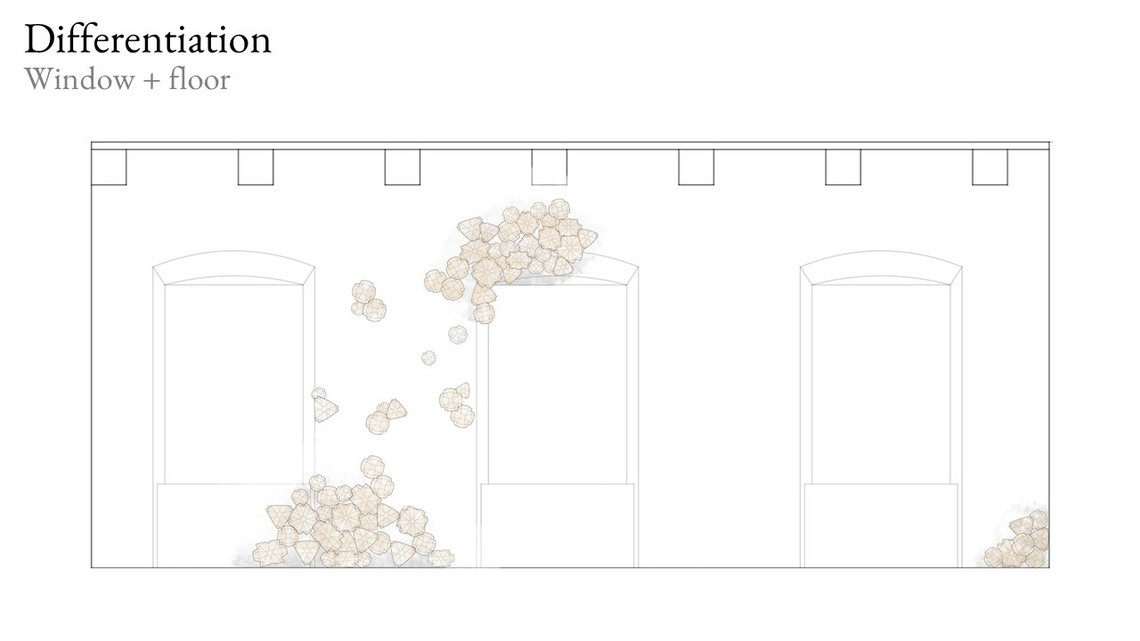

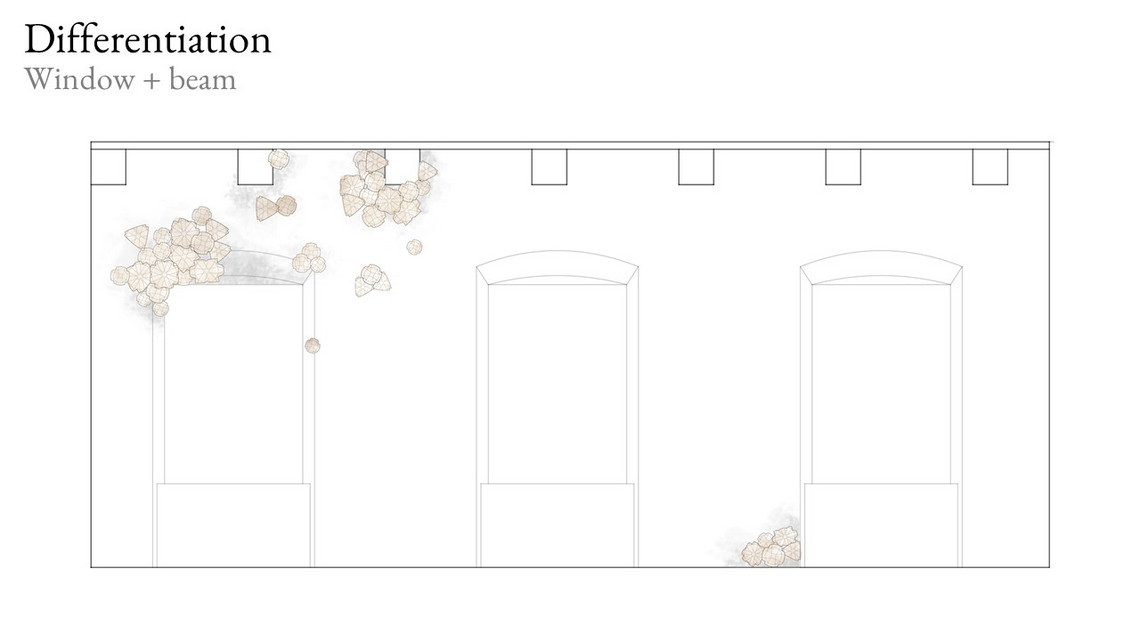

Spatial Impact

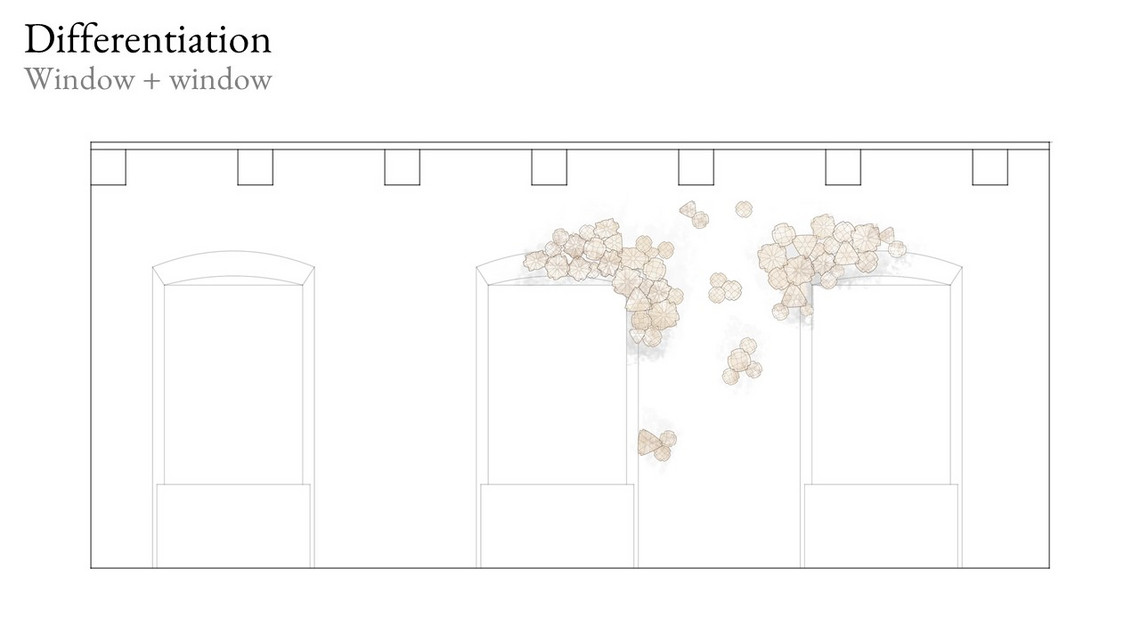

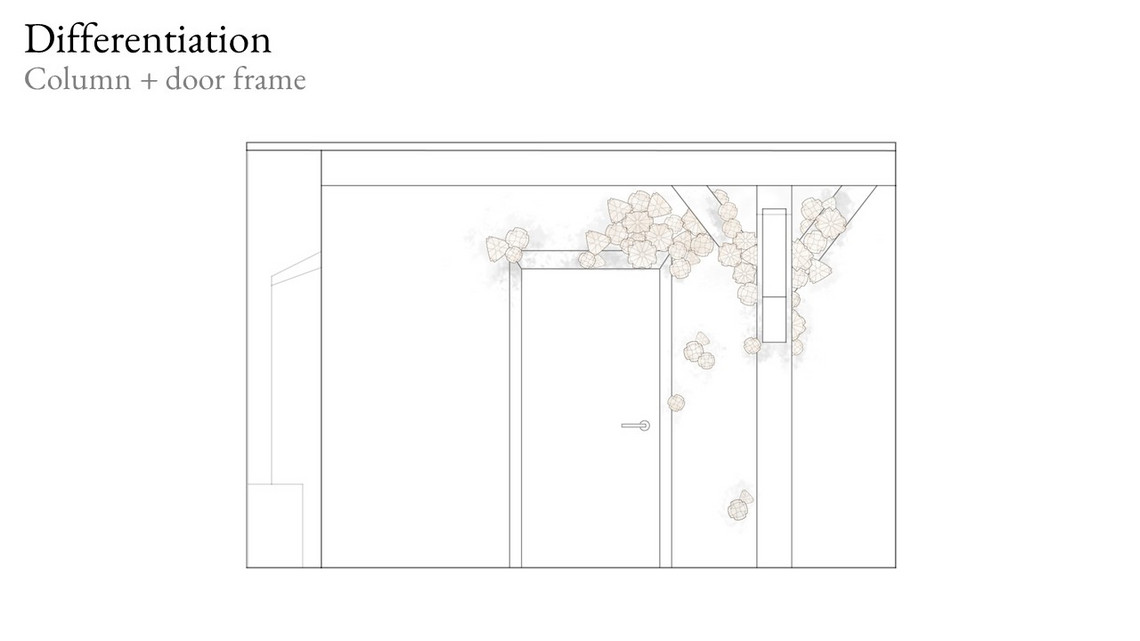

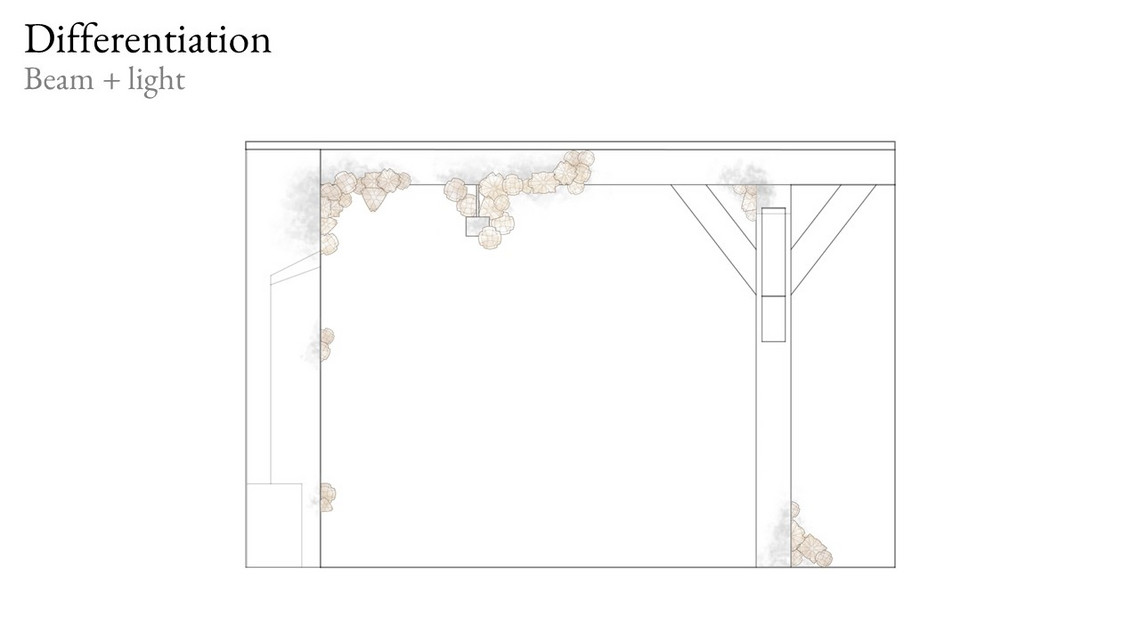

To speculate about the spatial application of the proposed composite, 3 different scenarios were explored through physical prototyping. A different configuration of 12 elements was introduced in each scenario and was explored with natural light and artificial self-illumination.

This strategy is based on the idea that architectural space is not only solid materials that should remain static and silent, but we should consider growing elements on the environment that can introduce performative aspects.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål