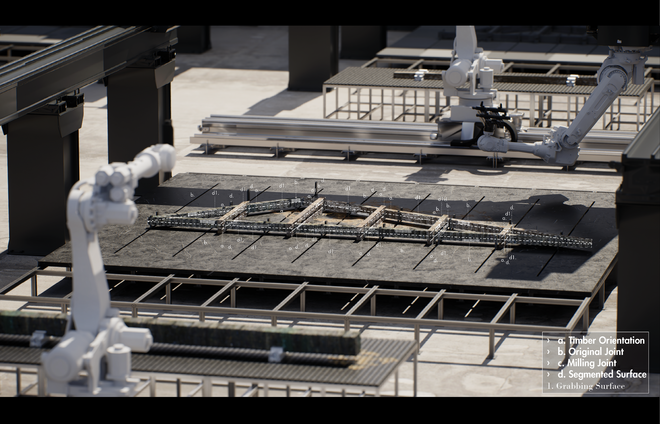

Robotic Adjustments in Reclaimed Timber Framework

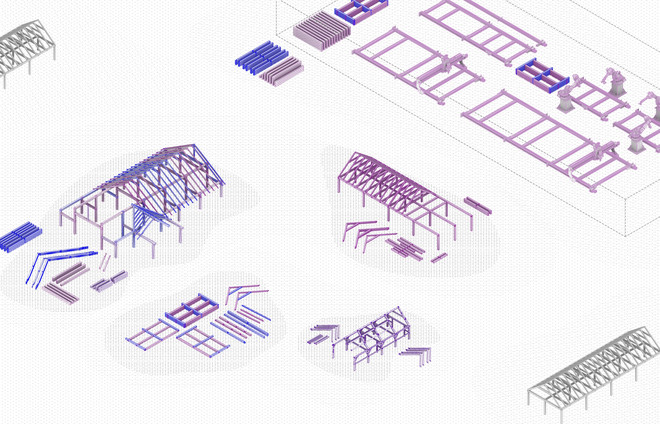

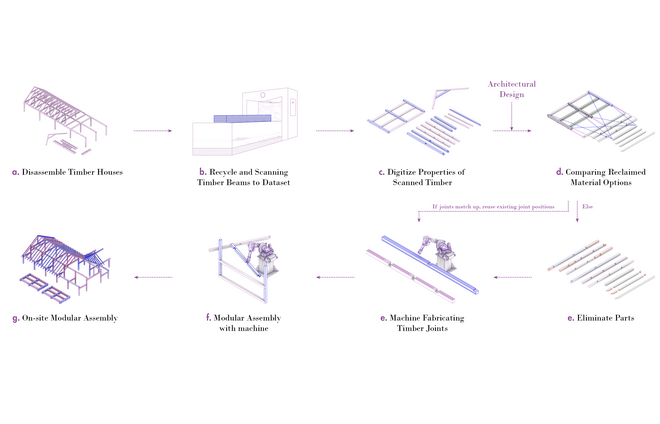

After disassembling buildings, they enter the circular economy and are usually degraded into smaller pieces through practices such as wood recycling, repurposing, and upcycling. The lifecycle of wood can be extended, reducing the need for new raw materials. To retain as much value as possible, we can use the piece as much as it is before entering the wood cascading process.

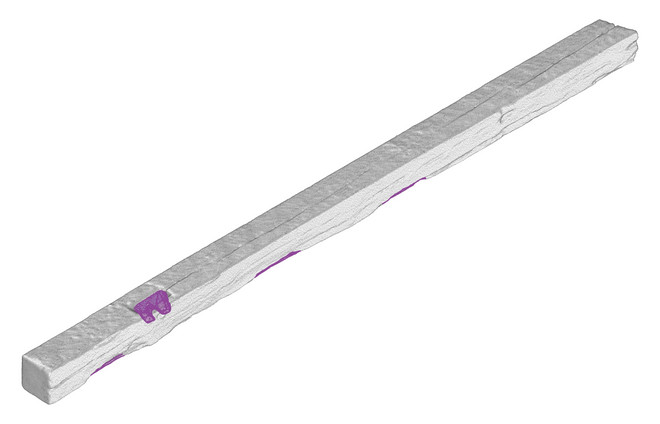

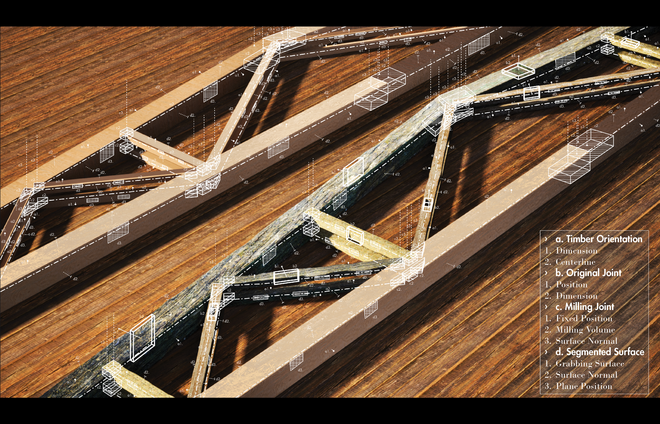

When the wood is being reused, we usually cut away the parts where the original joints exist, resulting in a shorter primitive material. Still, if these joints are kept, their sizes must be evaluated. We can reuse and re-machine the existing joints on the beam, minimizing the excess material being cut off.

How do we acquire and track material inconsistencies and enable the process of adaptive robotic assembly with reclaimed timber?

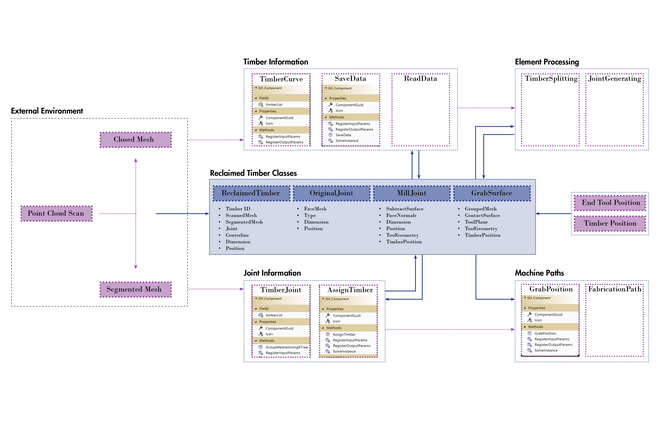

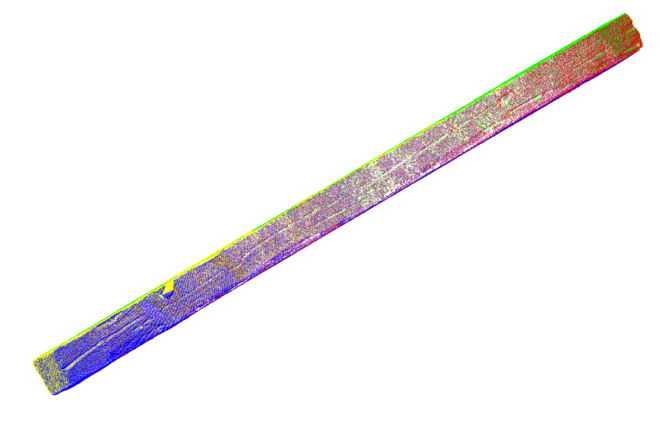

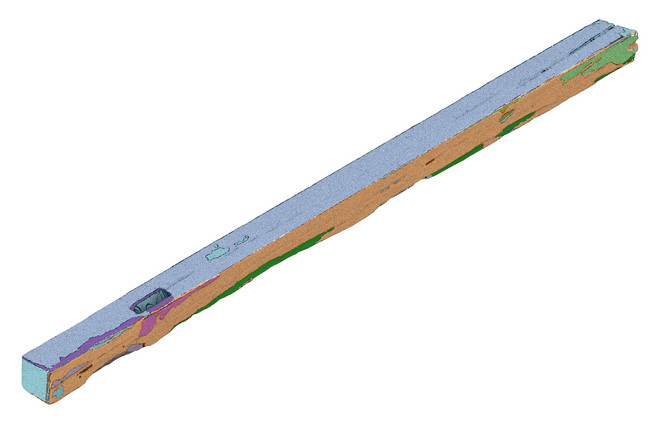

- Extraction of features from inconsistent material

- Customized digital tools within the design environment

- A digital framework to adapt fabrication information

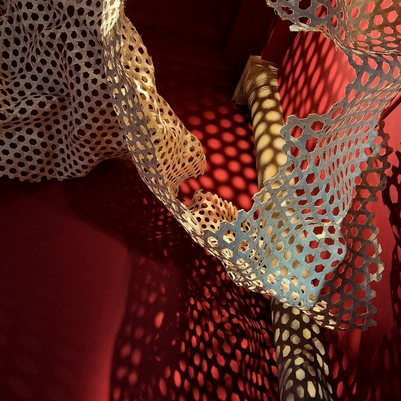

- Experiments on robotically applicable joints

Customized tools for reclaimed timber to design with minimal waste and making adjustments for fabrication

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål