Bundle - a biobased chair

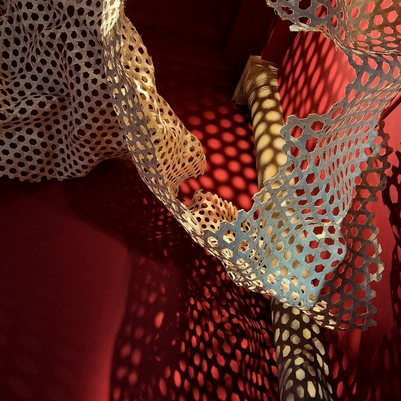

Bundle is the result of material-driven investigations of the potential of biobased composites in furniture design. The project was done in collaboration with Kirstine Sejersen. Through experimentation, we found a material composition and a set of design principles that allowed us to design a lightweight, mono-material chair. The chair is produced by thermo-pressing flax fibers and PLA into rigid shells.

When starting this project our goal was to enhance the properties of plastic-based products while simultaneosly reducing their environmental impact. Specifically, we wanted to increase the aesthetic appeal of plastic products and use less material in their production, without losing strength and durability. This can be achieved by incorporating flax fibers into a plastic matrix. The plastic matrix is a PLA derived from cornstarch making the composite both 100% biobased and biodegradable.

Our project comprised of four key phases:

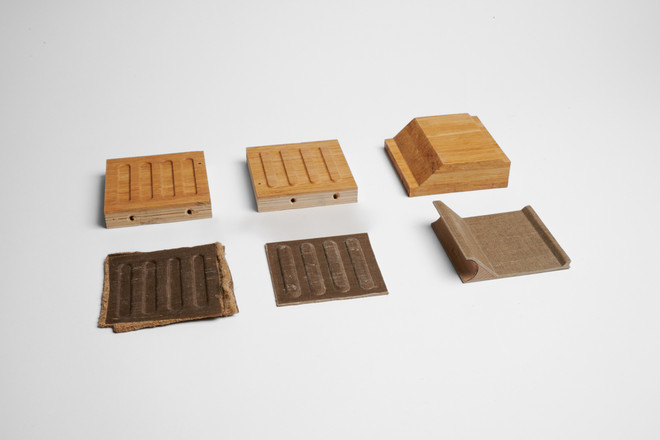

- Experimentation to establish the ideal composition of the flax/PLA composite

- Form investigations to understand the materials mechanical properties and to learn about possible ways of constructing products with the material

- A design process where we took our findings and implemented them in a monomaterial chair design

- A development and prototyping phase where 1:1 prototypes of the design were produced.

Bundle

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål