3D printing ceramics: A modular column system

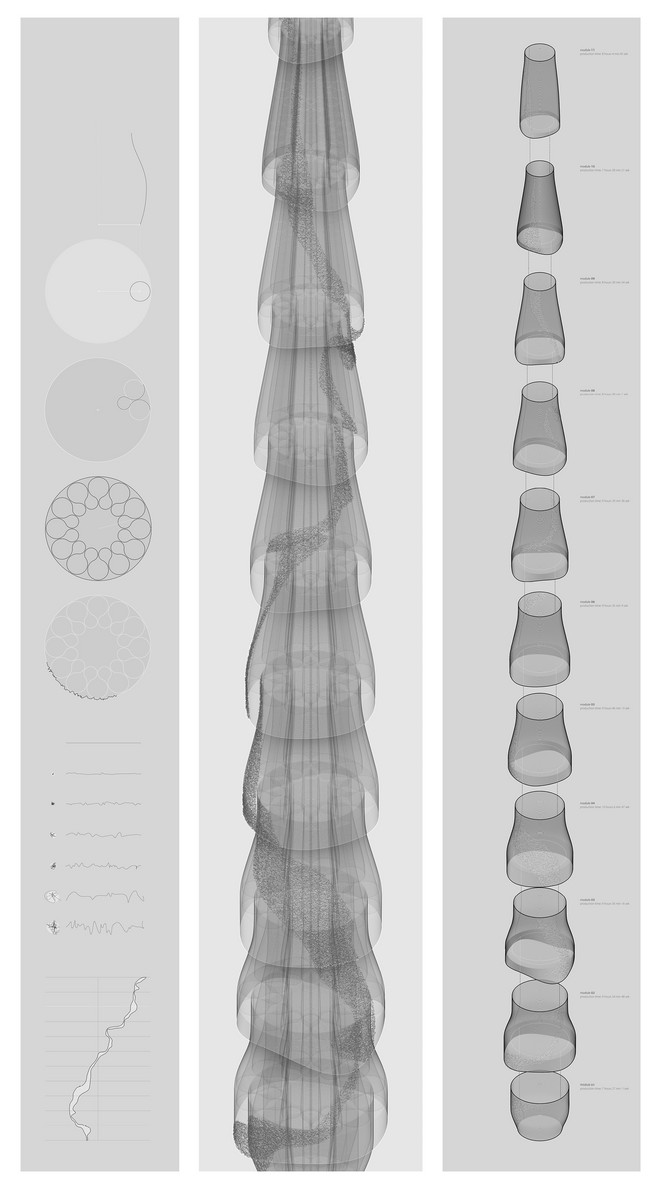

Building components such as the column change as new technologies emerge. Choosing the idiom of the column as site this project investigates the haptic and visual qualities of 3D printing ceramics on an architectural scale.

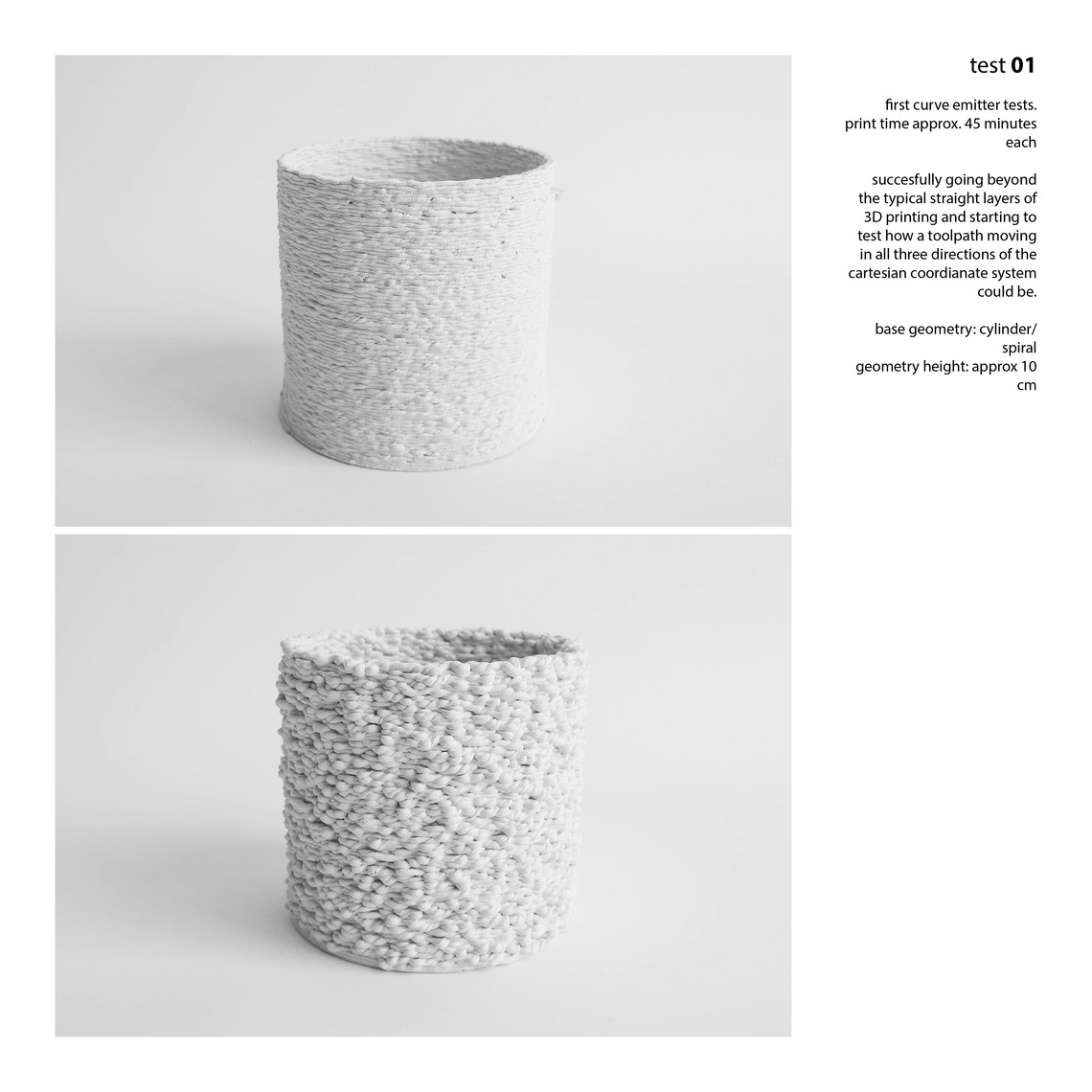

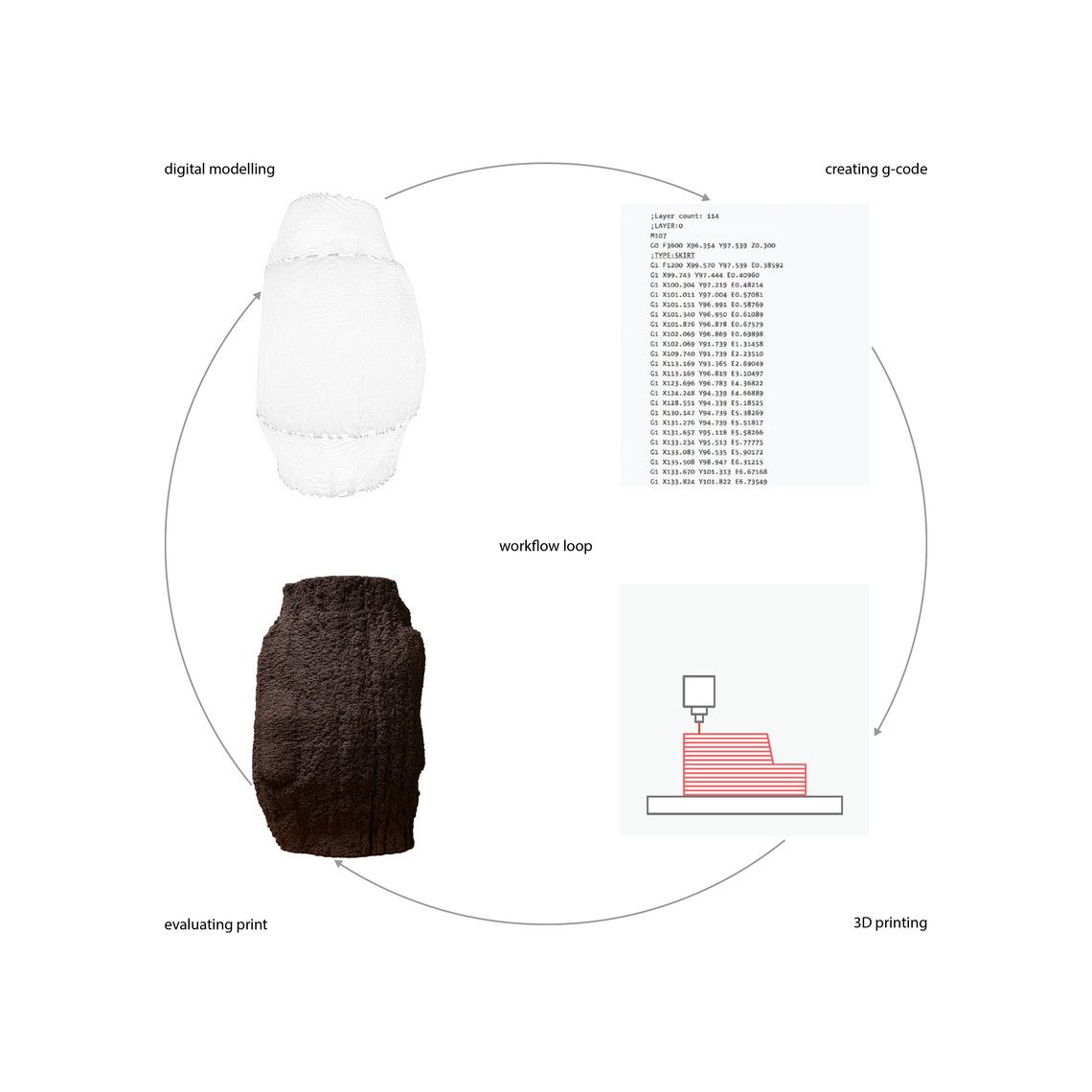

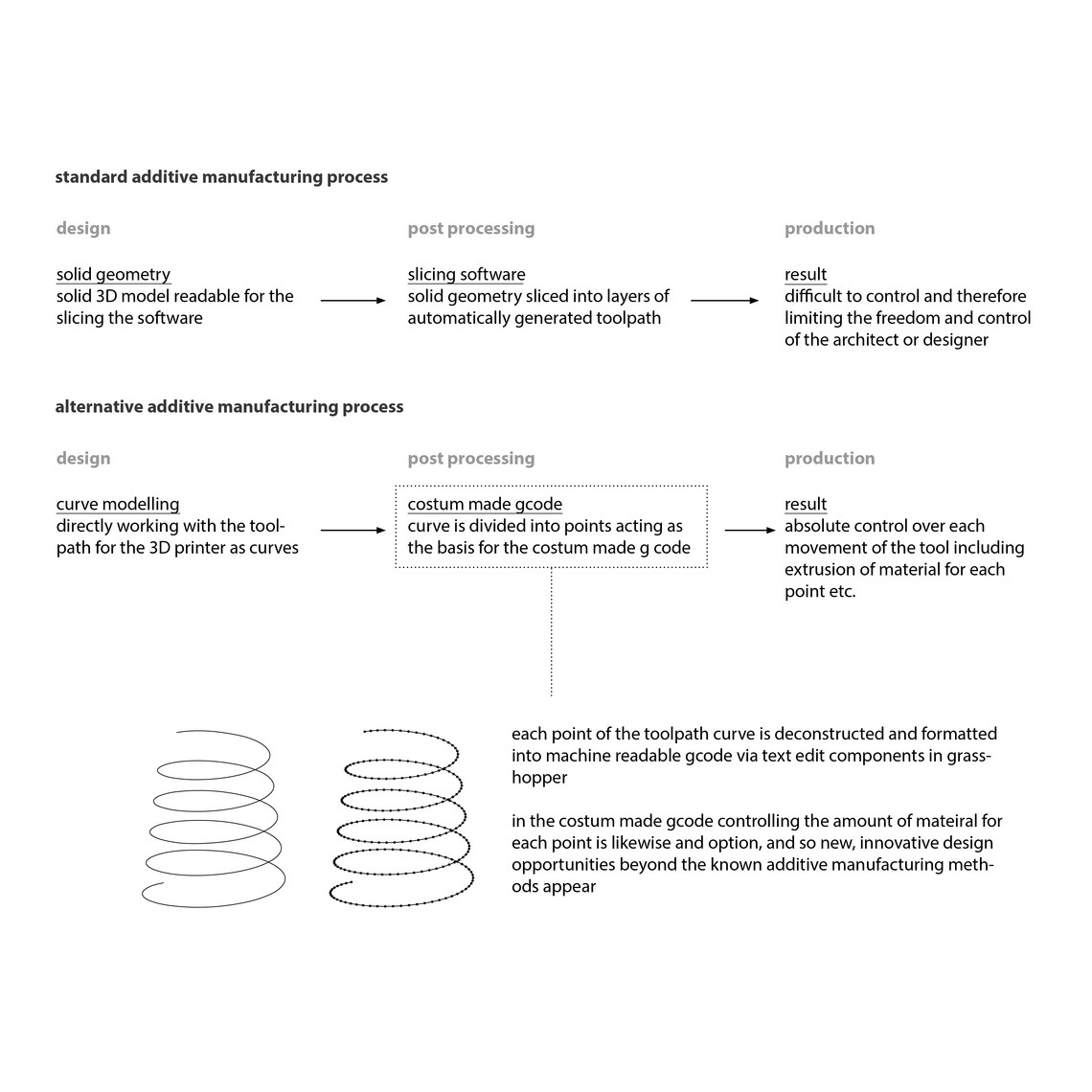

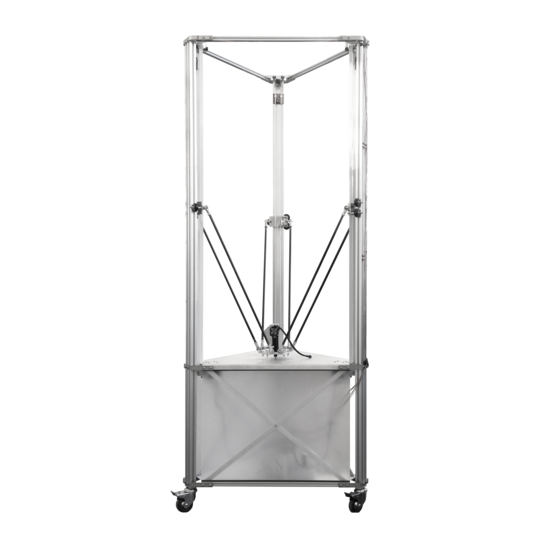

As a part of the project, to gain in-depth understanding of the process for additive manufacturing, I build a large scale 3D printer for ceramic materials and developed a digital setup to engage directly with the toolpath for the machine. This allowed me as an architect designing architectural components to fully engage with both the toolpath and the production parameters, broadening the potential of the fabrication method.

THE COLUMN AS AN ARCHITECTURAL COMPONENT

In the old greek temples the column was a highly structural element. It held up the roof structure, protected the structure against earthquakes, allowed a free planning of space and stories of the time was perpetuated into the columns.

Building components, such as the column, change as new technologies emerge. Now the columns from the ancient greek temples are merely symbols of the ruins, the last element still standing.

In the modern age the column was changed due to the introduction of steel as a primary building material, minimizing the size of the column and stripping away all ornamentation. Today innovative fabrication methods such as 3D printing are again changing the column as an architectural component, allowing a high level of articulation and the embedding of numerous functionalities into the column.

MODULARITY AND SPACIALITY

A column is a modular element, consisting of multiple parts. Together they can appear seamless (shaft) or highly differentiated (capital etc).

The column was an architectural invention which allowed for the support of ceilings without the use of solid walls, thereby increasing the space, which could be spanned by a ceiling, allowing the entrance of light and offering an alternative aesthetic to building exteriors.

THE DIGITAL COLUMN

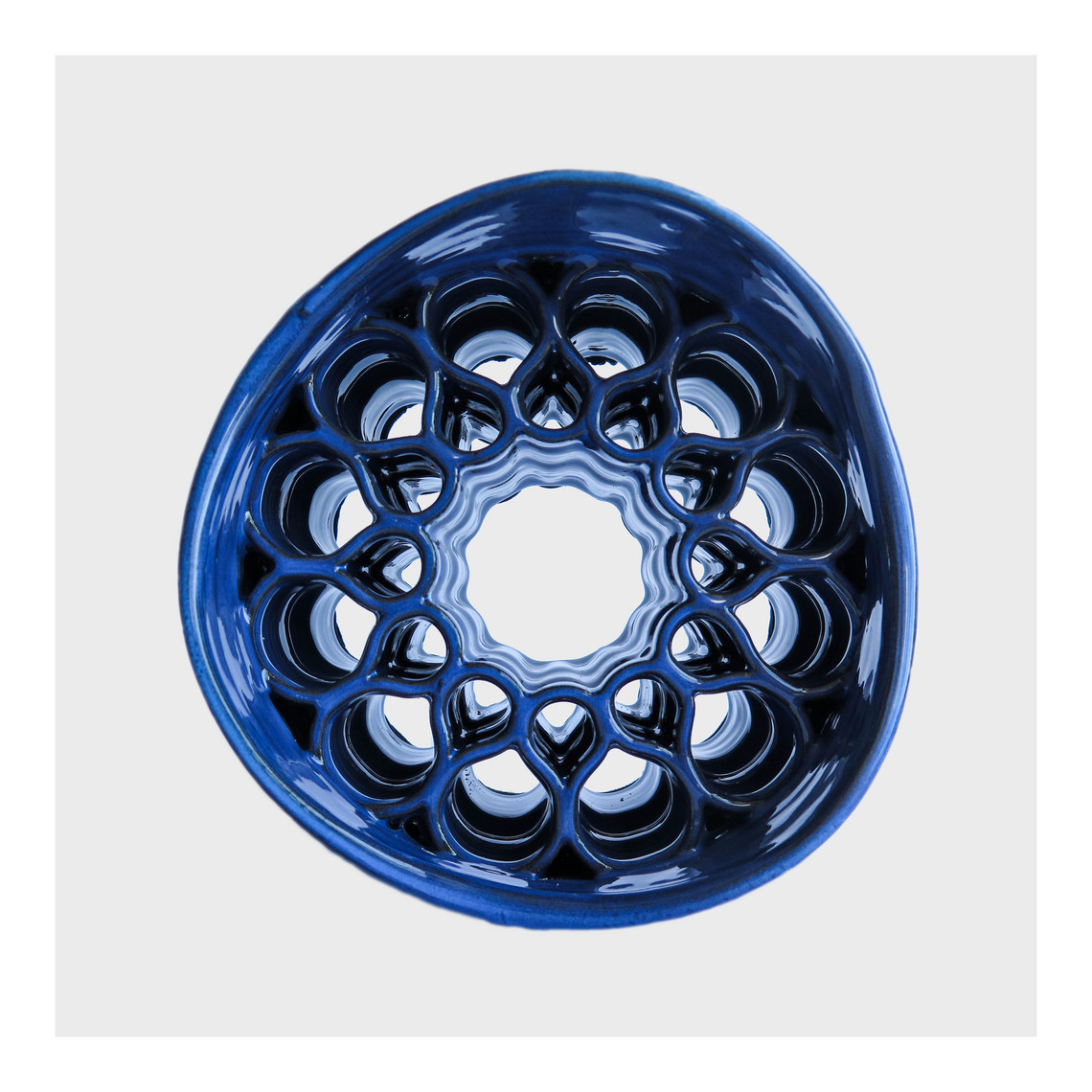

This project employs 3D printing ceramics as a fabrication method. Digital fabrication methods allow for highly articulated objects, without comprimising on fabrication time and precision. Additive manufacturing - including 3D printing - offers mass specialization without any waste molds.

Additive manufacturing do however become deliberately sterile, especially when working with materials such as plastic and steel.

ADDITIVE MANUFACTURING

OF CERAMICS

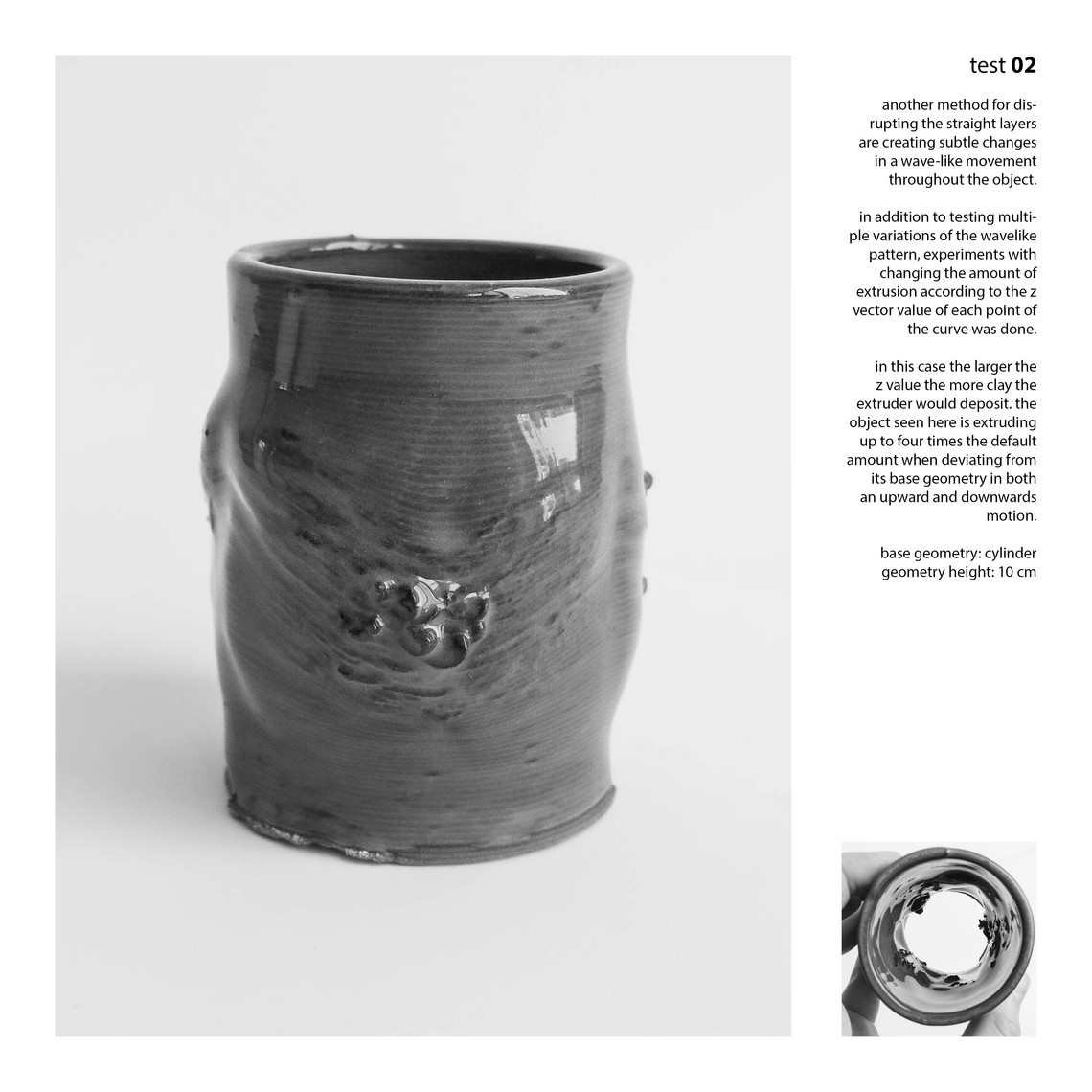

3D printing ceramics introduces another level of engagement in the 3D proces as well as it connects the digital fabrication to the material world on a very high level. When 3D printing with ceramic materials, a number of parameters emerge, including:

- Varying types of material properties

- Material behaviour during print

- Deformation during drying and firing

This project uses ceramic as material due to its qualities in terms of sustainability and the possibilities it offers in terms of building material, such as firing, glazing and variation in appearance through processing.

DEMOCRATIZATION OF MAKING

--- We shape our tools and therefore they shape us. ---

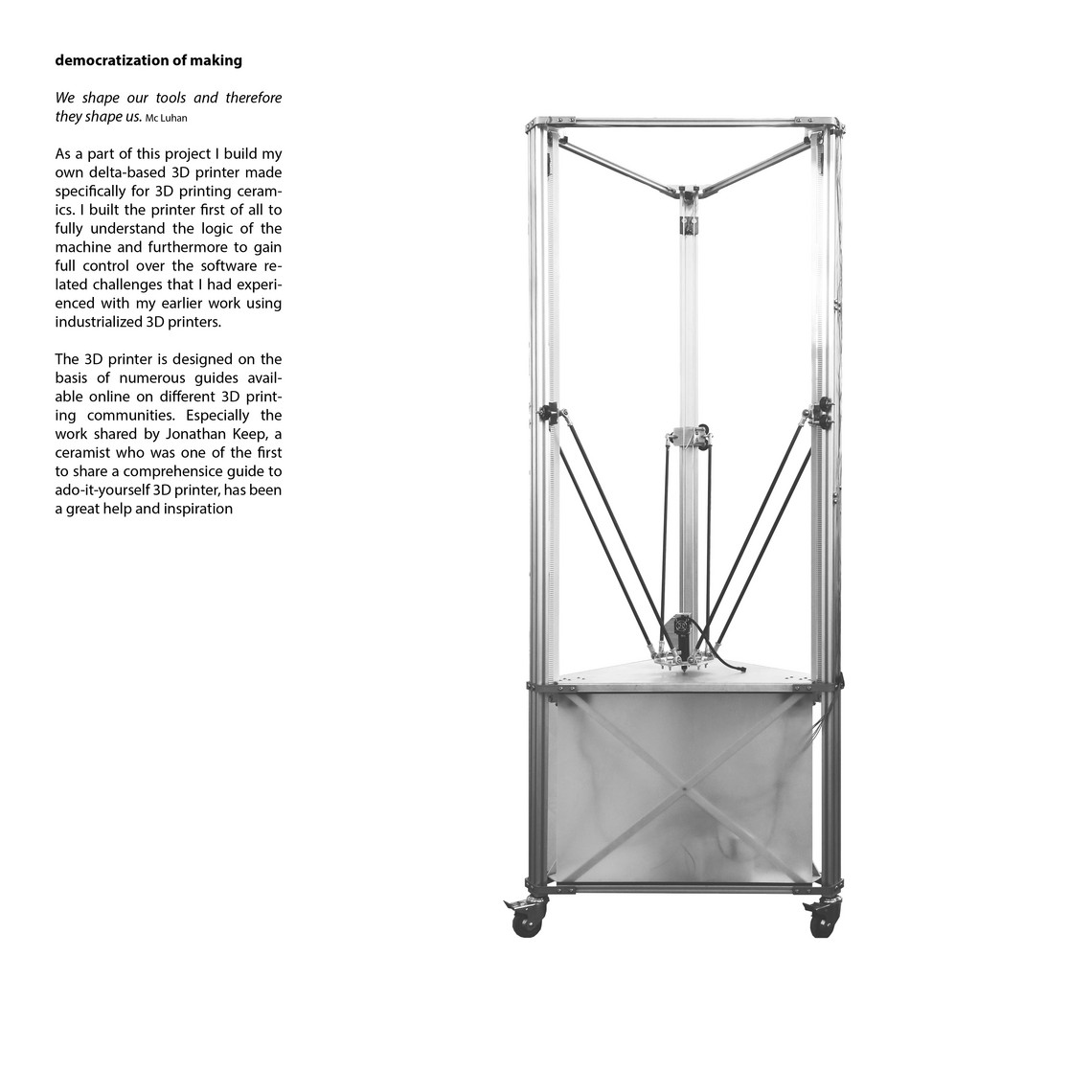

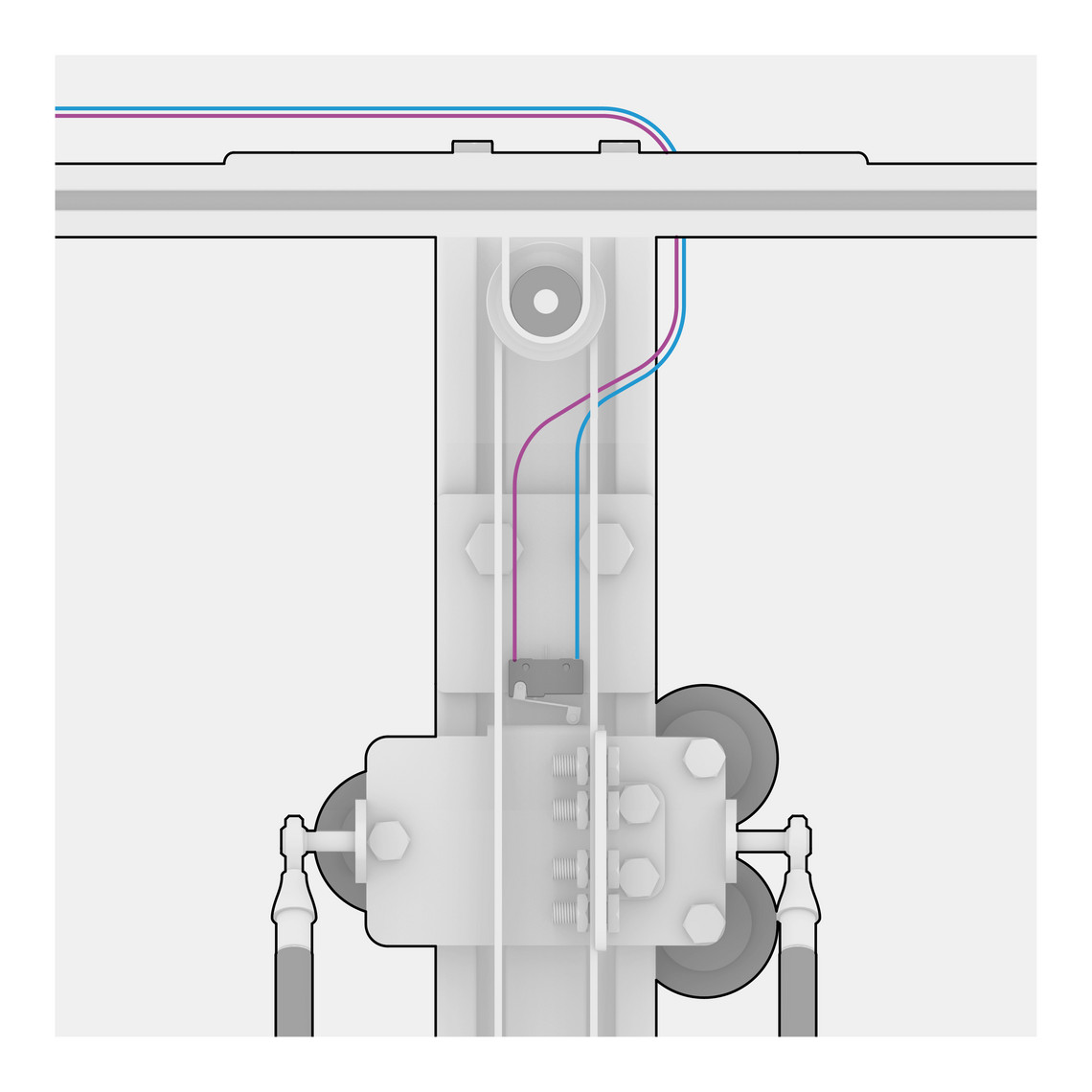

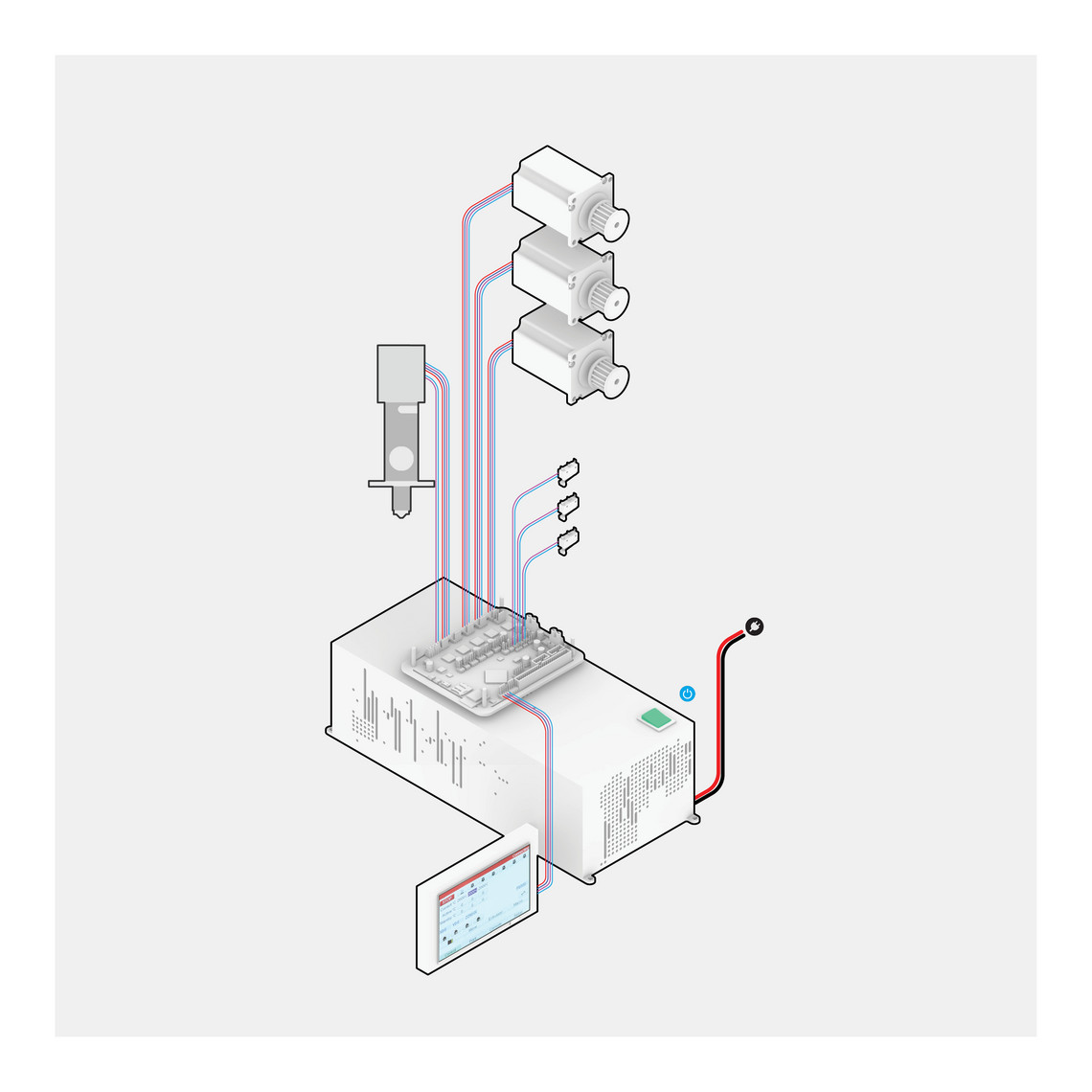

As a preperation for my thesis project, I build my own 3D delta-based printer made specifically for 3D printing ceramics. I built the printer first of all to fully understand the logic of the machine, and furthermore to gain full control over the software-related challenges and to be able to print with a large range of ceramic materials of different types and colours.

The 3D printer is designed on the basis of the numerous guides available online on different 3D printer communities, especially the work shared by Jonathan Keep, a ceramist who was one of the first to share a comprehensive guide to a do-it-yourself 3D printer, has been a great help and inspiration.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål