Løvskal Ochre

Local Ochre

For a long time, Natural Ochre colors were a stable in our color palette. A common pigment that was produced locally and used all over Denmark. Colors that represented our natural and cultural environment. In Løvskal, Jutland possibly the largest Ochre deposit in Denmark can be found. In 20th century Løvskal, an open mine extracted and produced beautiful Danish Ochre colors. But since its closure in 1965 no Ochre pigment has been extracted or produced in Denmark. We can therefore no longer experience and apply Danish Ochre colors. Instead, we chemically produce or import pigment.

Reestablishing Danish Ochre colors

Løvskal Ochre aims to revive the understanding & application of Danish Ochre pigment. To do so, a cabinet containing tools, samples & artefacts is produced. A cabinet treated with linseed oil made from burned Løvskal Ochre. A cabinet that materializes Løvskal Ochre pigments & investigates 3 future applications of Løvskal Ochre; textile dyeing; ceramic glazing and linseed oil, produced in collaboration with Linolie & Pigment. Løvskal Ochre seeks to reconnect us to the cultural and natural material fabric of Danish Ochre. I hope the spectator of this project leaves with an expanded perception of color. A perception grounded not only in the hue of color but also in the origin, history, culture, craftmanship and potential of Danish Ochre colors.

The mine

In 20th century Løvskal, an open mine extracted and produced beautiful Danish Ochre colors. But since its closure in 1965 no Ochre pigment has been extracted or produced in Denmark. Today the mine is a wild landscape of trees and ruins.

Applications

Løvskal ochre explore 3 different applications of the Ochre. Those are linseed oil, textile dyeing and ceramic glazing.

Linseed oil

Since the production of Danish Ochre ended 60 years ago it has not been possible to industrially produce oil or paint from Danish pigments.

Through a collaboration with linseed oil manufacturer, Linolie & Pigment the Danish pigmented oil has now been reestablished as two colors: raw and burnt Løvskal Ochre.

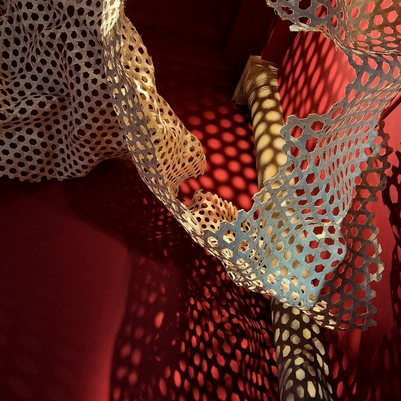

Textile dyeing

The textile dyeing industry consumes vast amounts of mineral water and applies poisonous metallic mordants to fixate the fabric

Within Ochre dyeing it has historically been common practice to use seawater as a dyeing medium and mordant. This allows for a more environmentally friendly method. This method was extensively researched within this project, on cotton and wool samples

Ceramic glazing

By adding different quantities of ochre to our glazing medium, we can archive shades of dark brown, yellow and beige.

The cabinet

The cabinet is the facilitator or the ambassador of the project. It communicates the full story: the context and all material experiments. It is a representation of a craftsman workstation and tool cabinet. Inside of it the ochre is materialized in all its dimensions. Both the cultural and historical perspective, as well as the material transformation from raw earth to refined pigment.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål