ReCraft - Reclaiming building materials

Introduction

This project focuses on the innovative repurposing of demolished construction materials, aiming to extend their lifecycle and introduce new building practices. By focusing on sustainable building methods and upcycling demolition waste into valuable construction resources, this work seeks to reduce the ecological footprint of the construction industry. This project is a collaborated effort between David Maximilian Schneider, Matti Elias Göran Kemppainen and Karoline Cecilie Aigner.

How can the reuse of construction and demolition waste be a systemic practice, rather than an exceptional?

About ReCraft

ReCraft revolutionizes the construction environment by minimizing waste and keeping materials in the industries loop. We reclaim demolition waste and transform it back into valuable resources, rediscovering its potential through traditional craftsmanship. By valuing non-standardized materials, we enable unique design possibilities and empower architects and builders to push creative boundaries.

THE DEMOLITION INDUSTRY

DEMOLITION INDUSTRY: EUROPE

Within EU 35% of the total waste that are produced annually come from construction and demolition sites, giving us the high number 950 million tonnes per year. It is a wide range of materials, bricks, concrete, wood, metals, glass and plastic, also toxic materials like PCB based products and asbestos. Methods for separating and reclaiming construction & demolition debris are established and widely available and generally cost-effective. However, the extent to which construction and demolition waste is recycled and its materials recovered differs significantly throughout the European Union, spanning from under 10% to 90% (Interreg Europe, 2024).

RECRAFT RESOURCE

ReCrafts resources derive from demolition sites in Denmark, with a focus on the Copenhagen region. These buildings vary widely in their original functions and sizes but share a common construction period from 1960 to 1981, resulting in some overlap in the materials available. The demolition processes we encounter are equally diverse. In one instance, we sourced materials during an active demolition. In another, we arrived at a site that had been partially cleared over four years ago, leaving some materials behind. In yet another case, we accessed a site that was in its pre-demolition phase, still awaiting its demolition date. These different scenarios require us to adapt our strategies and methods for recovering materials to ensure that we maximise the potential of each site.

RECRAFT PROCESS

The process began with visits to various demolition sites to find a variety of materials. We documented these materials and their unique elements thoroughly. This was followed by an experimental testing phase in which we assessed the potential and value of each material. This hands-on experience provided crucial insights into the materials‘ limitations, which helped us decide which materials to prioritise. With a deep understanding of the materials, we began to design creations that utilised their specific properties. Whilst making each piece by hand, we also explored suitable production techniques to scale up our operation and automate some of the manufacturing process.

RECRAFTED

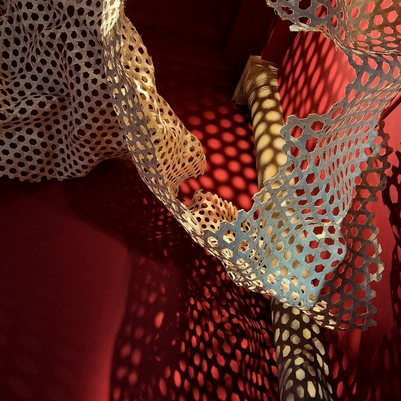

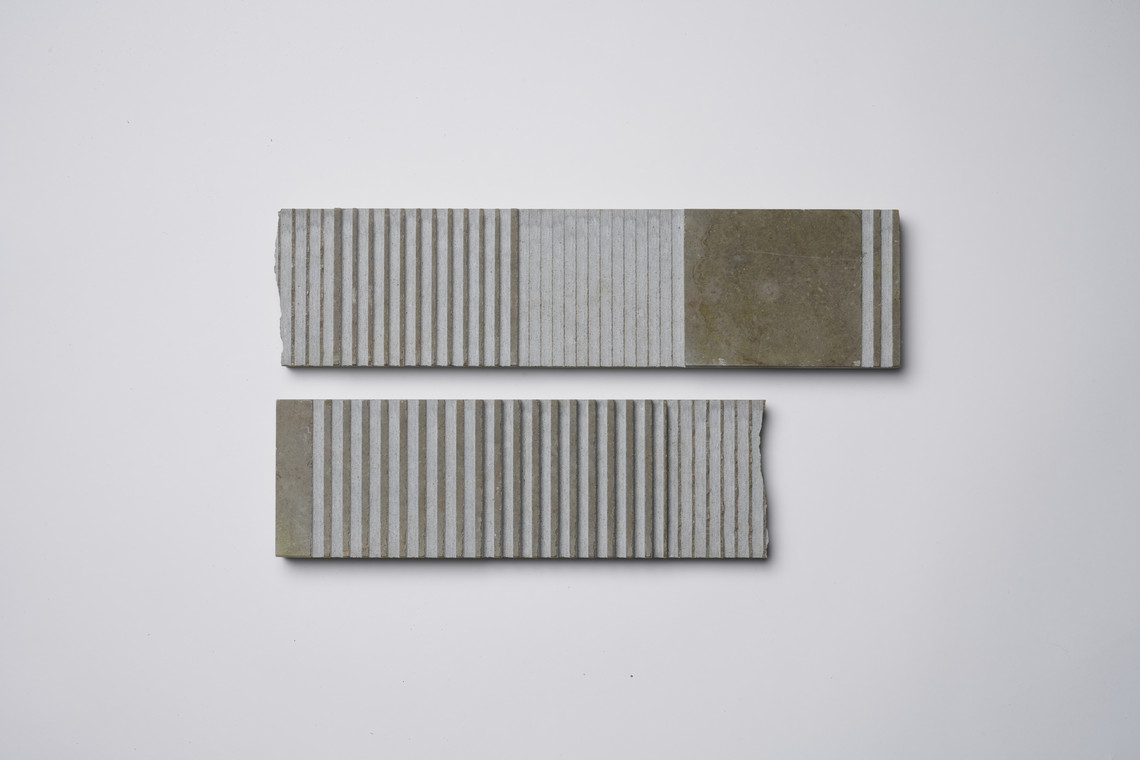

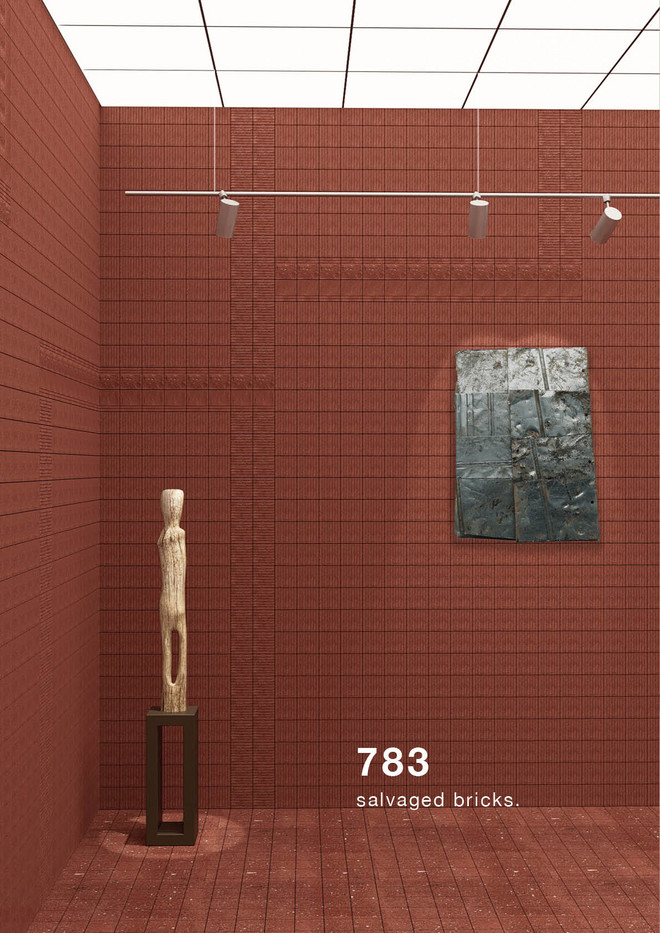

The first ReCrafted materials are interior elements such as flooring and wall tiles or cladding, available in various shapes, colors, and textures. These products originate from three different demolition sites and belong to two seperate collections.

The Høje Taastrup Collection features materials from the former Muni-cipality Hall of Høje Taastrup, including pine wood elements and the Textured Taastrup Tiles. The design approach for these materials primarily involves surface work, utilizing techniques from various crafts applied to the reclaimed resources.

The Element Collection is named after the prefabricated concrete elements used to replace other construction materials during the construction time of the demolished buildings. These elements were prefabricated and assembled on-site, which saved both costs and time. Materials from the Element Collection have sustained more damage, as they have already undergone the demolition process.

RECRAFTED AESTHETICS

Salvaged building materials from demolition work can be reused in a new architectural context and look aesthetically pleasing! The use of our product portfolio in the design of everyday spaces offers unique design possibilities and allows creative boundaries to be pushed. By upgrading and re-standardising non-standard materials, we make it possible to extend the life of the materials in a new architectural environment.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål