REWOOD

REWOOD - from wood waste to new use

In the future, as we move towards ash-free energy, surplus wood residue will pose a challenge. My solution is to repurpose wood residue from sawmills for applications in design and architecture. By experimenting with different scales, I aim to create efficient designs that maximize the new material properties of what I call Rewood. My goal is to ensure that Rewood contributes to environmental sustainability and reintegrates into the value chain, adding higher value and becoming a marketable, usable material.

Background

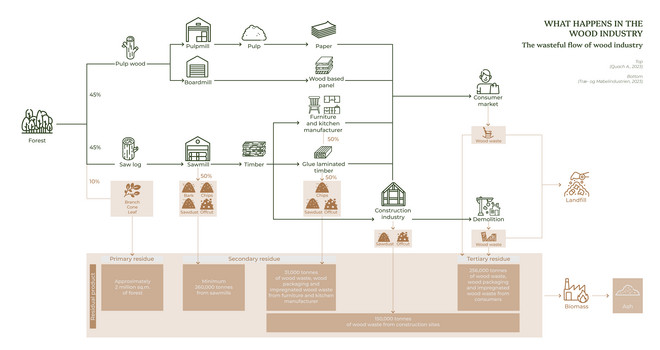

Wood is a widely utilized material, serving purposes from furniture to construction. The construction industry, in particular, increasingly relies on wood. In line with Sustainable Development Goal (SDG) 12, which focuses on responsible consumption and production, and SDG 13, which emphasizes climate action, I began examining the wood industry. My investigation starts from the very beginning, tracing the journey of wood products before they reach consumers.

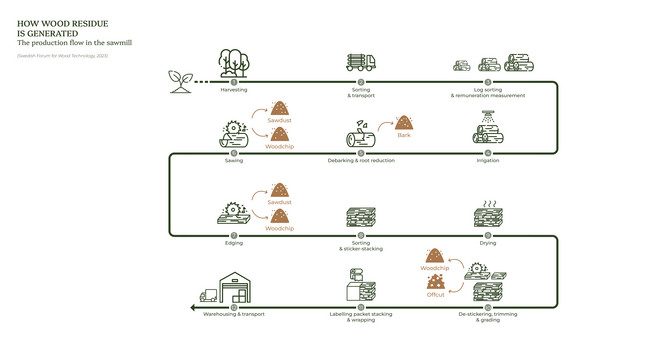

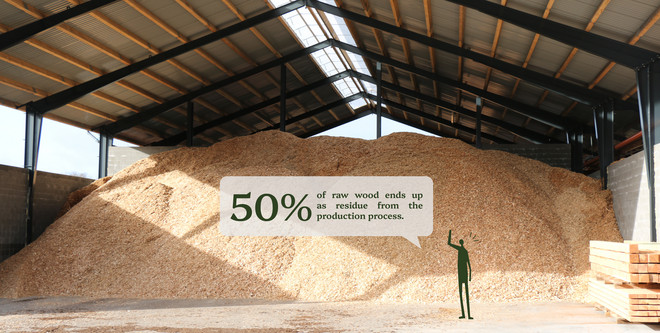

At the outset of the wood industry, sawmills generate significant wood residue, with 50% of saw logs turning into waste, amounting to approximately 260,000 tons annually. Wood is cut multiple times throughout the production process, resulting in residue of various forms and sizes accumulating in the sawmill.

“ What we dream of is that wood residue could be used for something more ingenious, that you could get a higher value for, so that it becomes a more valuable resource. That development is a bit slow. ”

-Træ- og Møbelindustrien, 2023 -

" How can I repurpose wood residue from sawmills for application in design or architecture? "

Approach

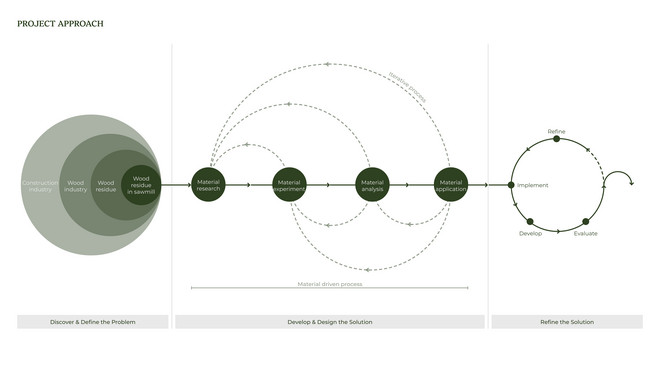

In my project approach, I started by discovering and defining the problem. I began with an exploration of the construction industry, which has a significant influence on wooden structures, followed by an investigation into the activities of the wood industry. Specifically, I focused on wood residue from sawmills as the starting point for my material-driven process. This involved conducting research, experimenting with materials, analyzing their properties, and exploring potential applications for new materials. This iterative process entailed trying various approaches, refining solutions, and further developing materials. Ultimately, I integrated these findings into design proposals alongside strategies for the value chain.

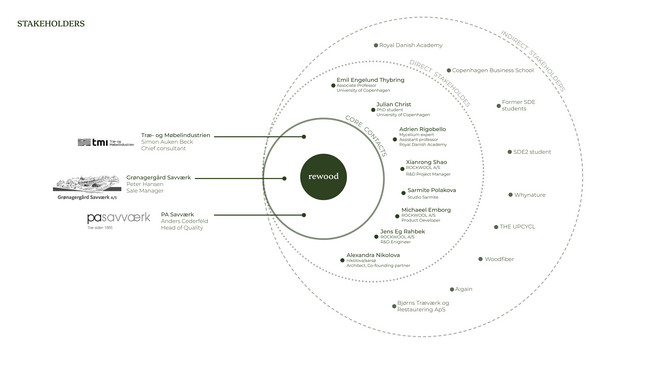

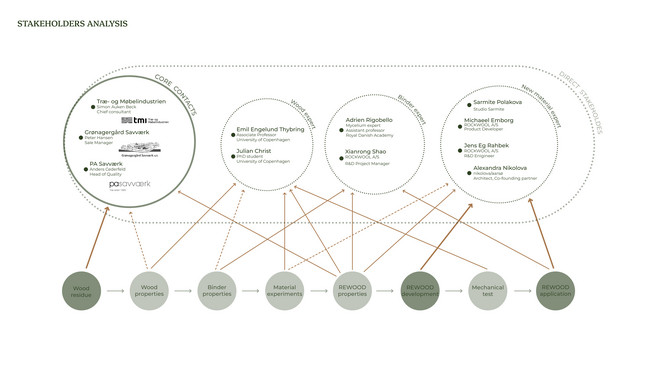

This project was significantly influenced by stakeholders, primarily the Træ- og Møbelindustrien (TMI), the Grønagergård sawmill, and the PA sawmill. These stakeholders provided materials, facilitated visits to their facilities, and enabled direct contact with experts in wood, binders, and new materials. Additionally, inspiration was drawn from indirect stakeholders who had previous experience with wood or wood residue.

Material-Driven Process

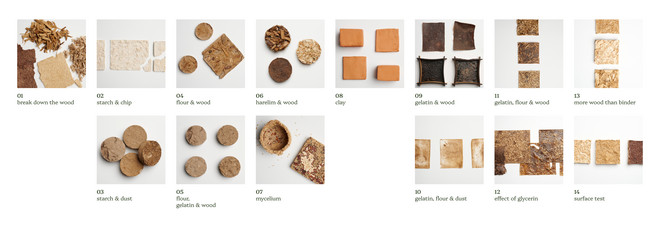

The material-driven process involves four steps. It begins with material research to understand the properties of wood residue. Next, I conducted 14 material experiments, which led to material analysis where each material produced exhibited different properties and strengths. The process concludes with material application, summarizing and determining the uses for this new material I call Rewood. These steps are iterative, allowing for constant revisiting of previous stages.

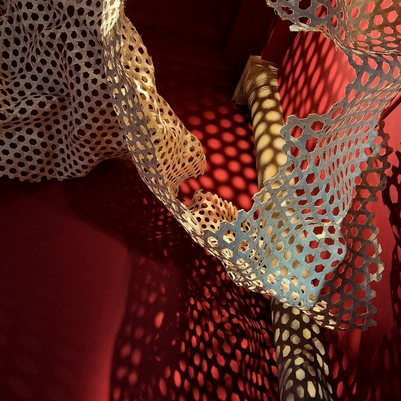

Rewood, created from experiments using more wood than binder, demonstrated significant properties, such as the ability to withstand weight without collapsing when pressed. Additionally, the material retained its compostability, suggesting it could be suitable for short-term use. Packaging, particularly protective packaging, emerged as a potential application where Rewood could have a significant impact.

REWOOD Development

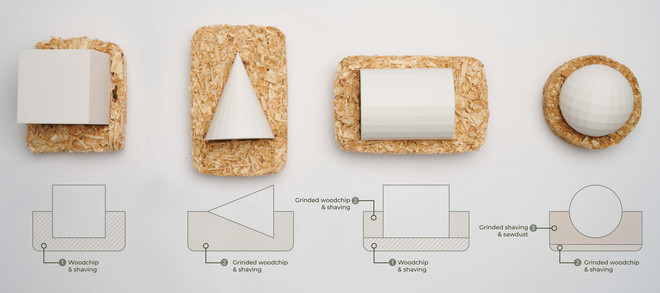

Protective packaging materials are designed to safeguard products from damage during shipping and storage. EPS packaging (Expanded Polystyrene) is commonly used to secure items during transit and warehousing, particularly for heavy, fragile, or irregularly shaped goods. Rewood, a material crafted from wood residue and a bio-based binder, is notable for its durability and ability to maintain its shape under pressure. It can be manufactured to be both hollow and lightweight.

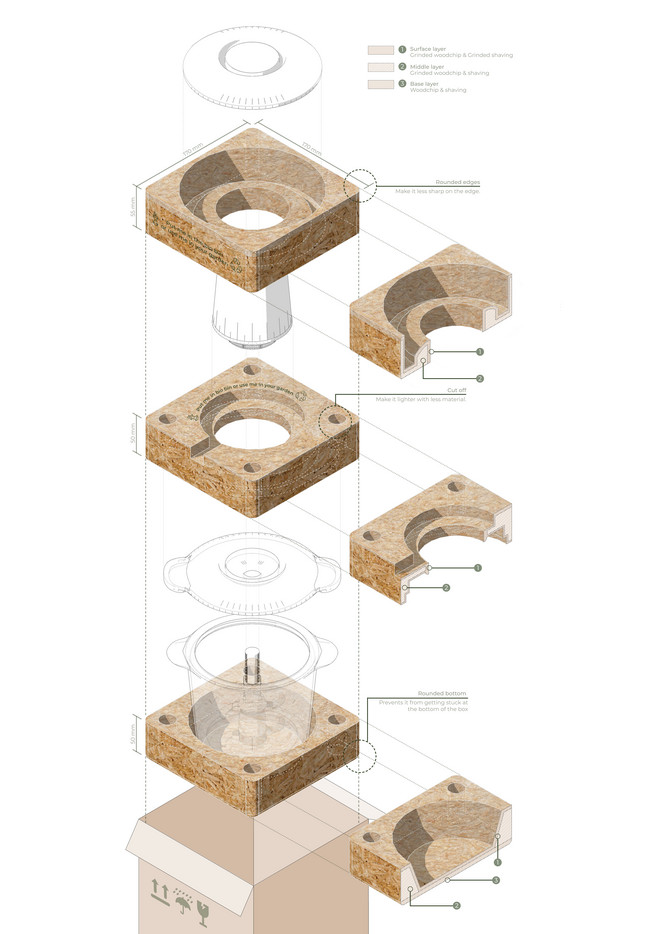

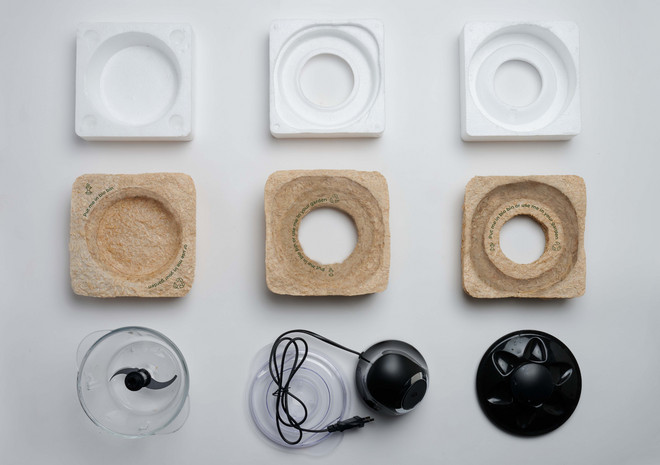

Rewood is created by refining a formula that uses more wood than binders and experimenting with different combinations of wood residue. The surface layer is developed from the gelatin experiment group, transitioning from rough to smooth, and ultimately achieving a balance that is soft yet firm.

REWOOD design proposal

I replaced the EPS protective packaging of a blender with Rewood. The blender is heavy, fragile, and complex in shape. The Rewood packaging features a rounded bottom to prevent it from getting stuck in the box, cutouts to reduce material use and facilitate removal, and rounded edges for a smoother feel. It also includes disposal instructions for proper placement after use. Rewood enhances the customer experience when they receive, unbox, and handle the product. The wood-like material provides a non-plastic touch, improving the unboxing experience. Thus, Rewood not only enhances customer satisfaction but also offers environmental benefits, positively impacting the brand and society.

REWOOD Strategy

EPS is a commonly used material for protective packaging, ensuring safe product delivery. Although it is 100% recyclable, only 35% is actually recycled, with most ending up in residual waste. Replacing EPS with Rewood made from sawmill wood residue, offers a sustainable alternative. Typically, this wood waste is used for biomass, but Rewood extends its life by serving as protective packaging, ensuring products reach customers safely. Rewood can then be returned to biomass for energy production. In the future, a waste collection system for Rewood could allow it to be recycled into new products or packaging. Currently, Rewood's compostable properties enable it to be disposed of in bio-bins or used as garden woodchips, returning it to nature.

Rewood provides a sustainable solution for protective packaging, addressing the issue of post-consumer waste that often escapes recycling. Both producers and consumers can make responsible choices, reducing waste and preventing environmental problems from improper disposal.

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål