Robotically Fabricated Ice Formwork

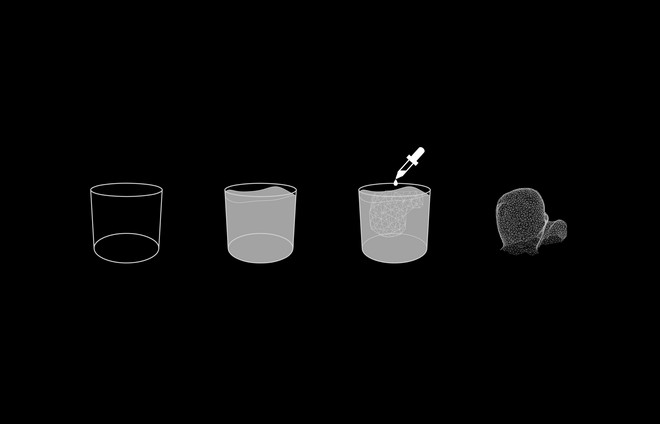

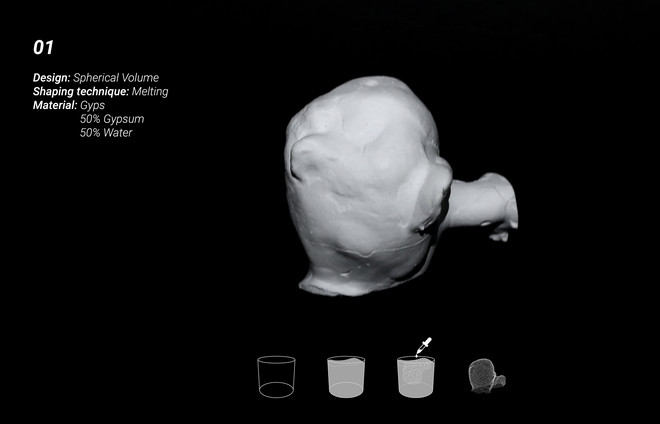

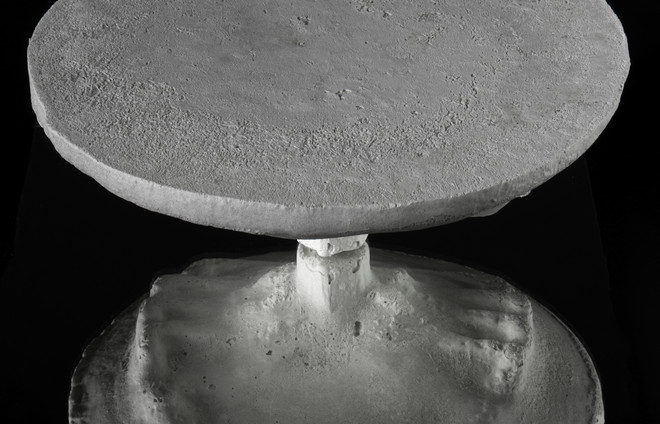

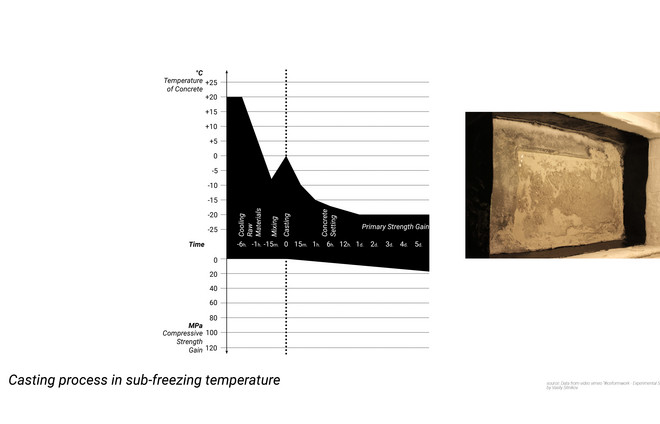

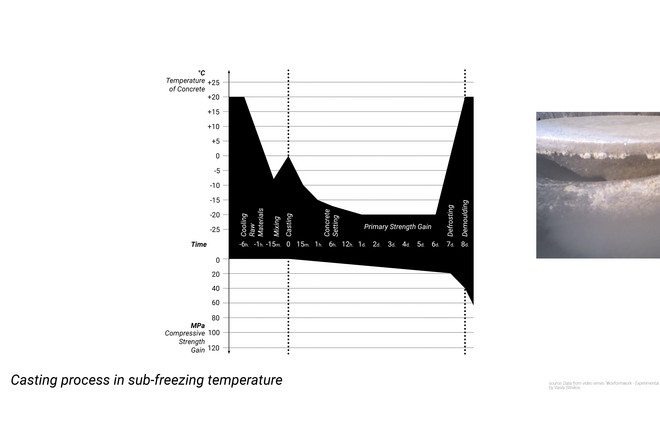

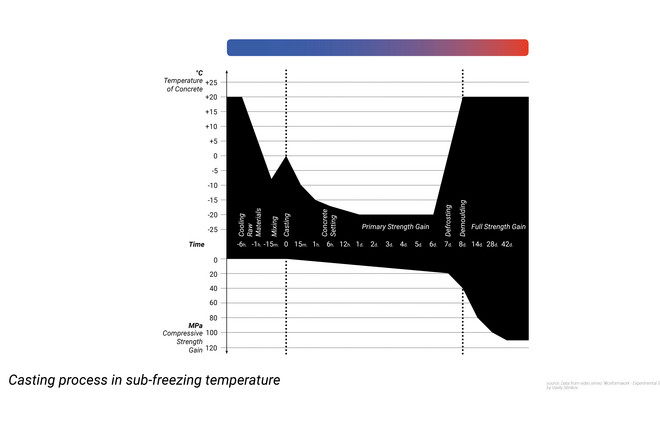

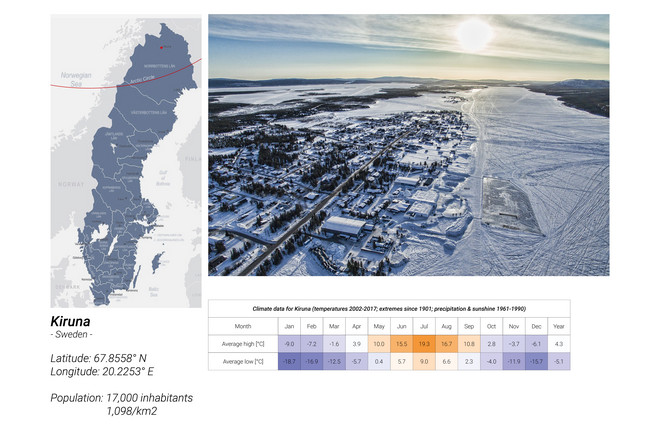

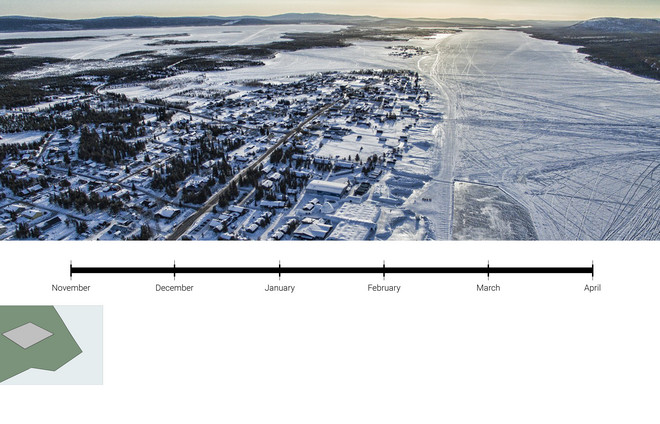

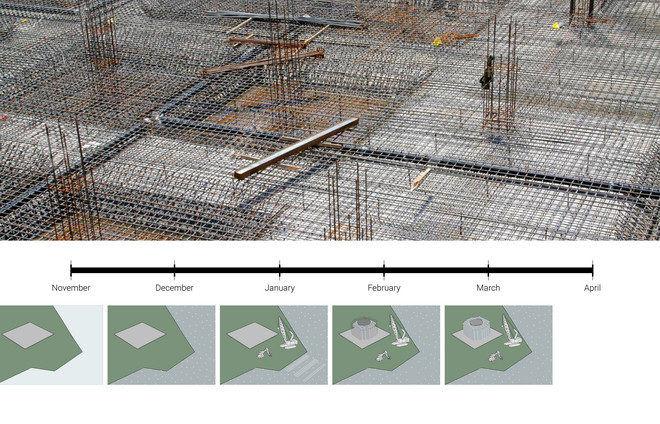

This Master Thesis focuses on the exploration of casting complex concrete architectural elements with ice formwork.

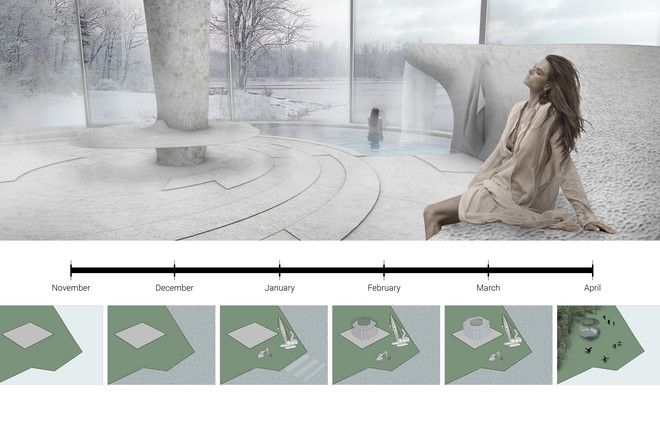

With the latest advances in complex geometry building components, we are moving from producing architectural elements from the construction site to a more controlled environment.

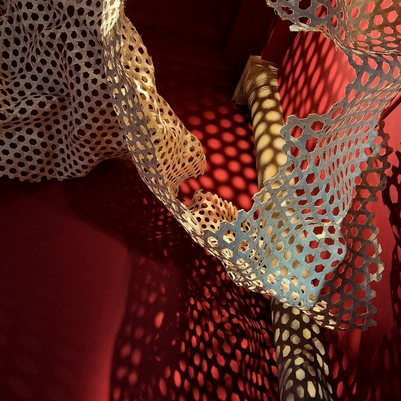

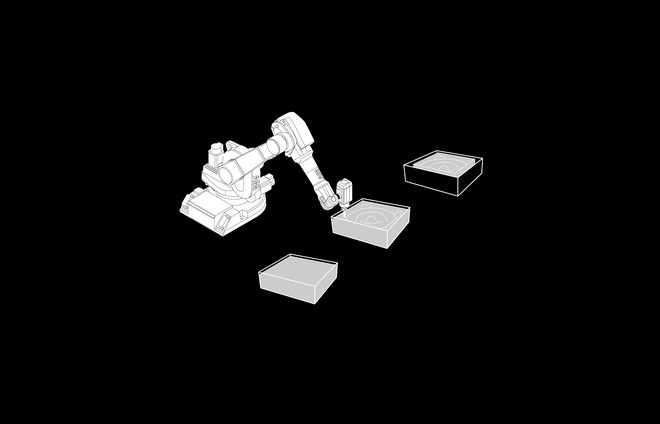

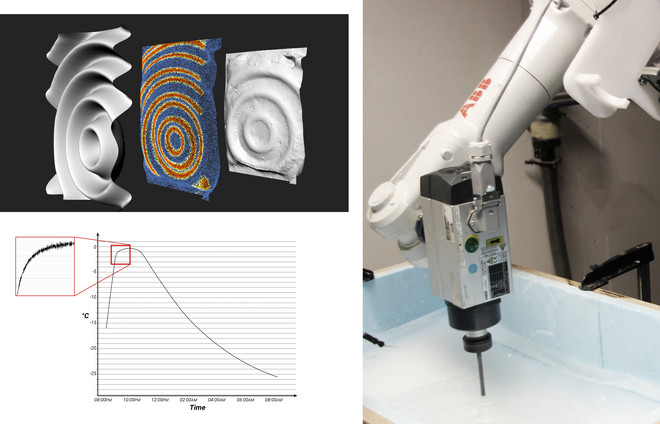

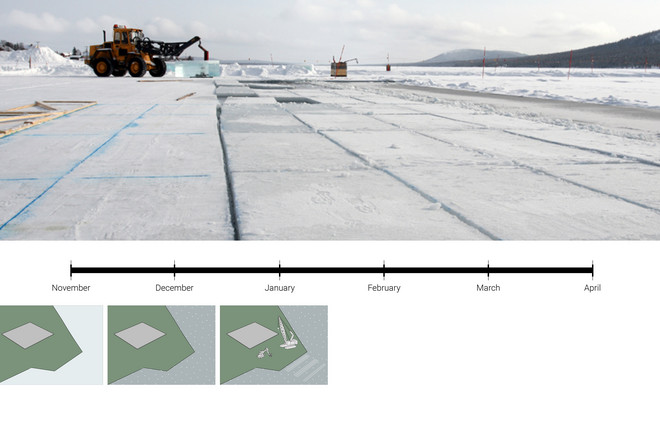

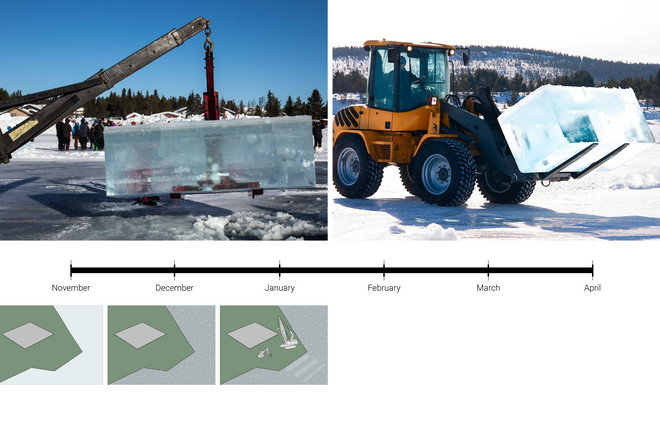

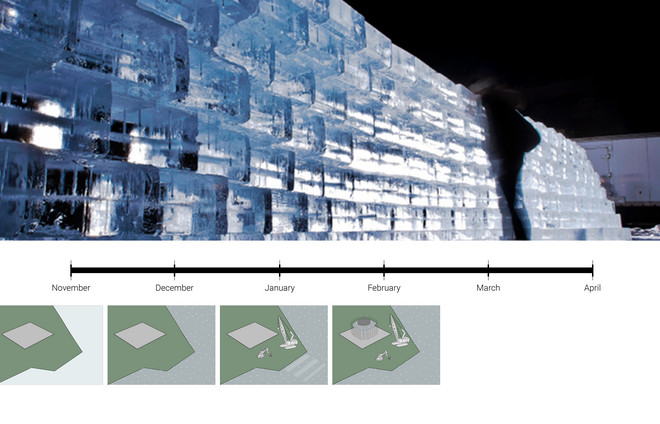

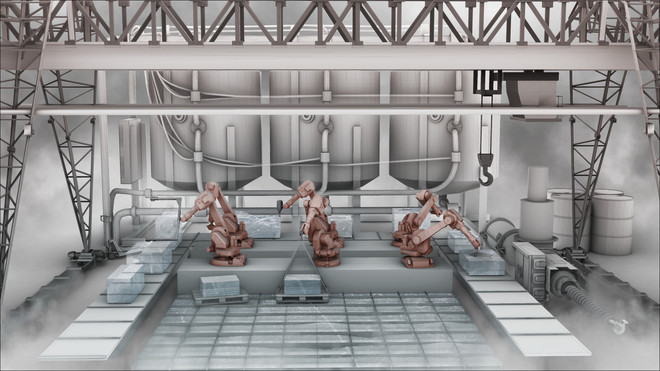

Due to the dynamic behaviour of the ice, these can be produced by reusing the same mould material and maintaining high standards of quality. Using robotic fabrication tools such as a robotic arm milling, the goal is to achieve 3d shapes made from one or more ice moulds, able to be stacked, assembled and merged together in order to define architectural partitions.

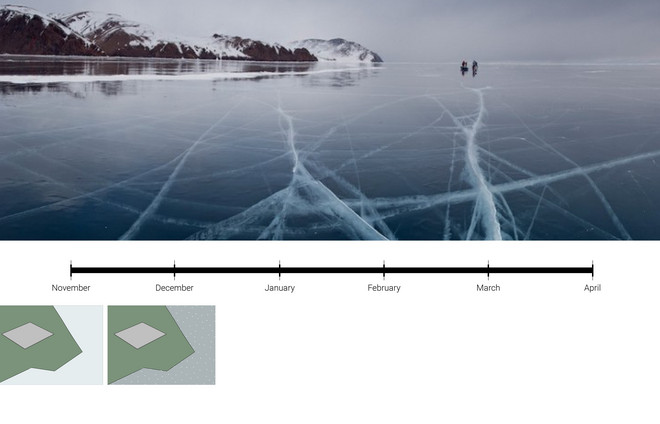

One of the main instigators of this research is sustainability, showcased both through the usage of ice as a mould material that is 100% reusable, and of the possibility to create complex geometries for structural optimization of the topological distribution of concrete into the cast. The potential of using ice as the formwork material is that of unity and being able to have a bespoke shape for every single element. The fabrication process is continuously iterated and improved through the iterative 3d scanning of casted objects and compared with the digital model to increasingly embrace morphological material programming.

The use of ice as a formwork material is a novel methodology that has been adopted into an architectural process to precast concrete elements. The advantages offered are the possibility to create a sustainable mould employing a 100% recyclable water while having low limitations in the complexity of the object’s geometry. Moreover, ice aesthetic unicity reflects bespoke topologies for each element.

An initial exploration using two evolutionary algorithm (EA) to optimize a flooring partition has been initiated. Employing “Karamba” as a parametric engineering and structural modelling for Grasshopper, has been compared “Galapagos” with “Octopus”. Both EA completed the task with different results, but the second EA produced a better result because had the option of marking preferred results and this allowed the designer to re-adjust the goal desired during the computation process.

Using topology optimization analysis, the amount of material has been reduced by 73%.

The prototype has been successfully cast and self demold using concrete fibre-reinforced.

Portfolio

Det Kongelige Akademi understøtter FN’s verdensmål

Siden 2017 har Det Kongelige Akademi arbejdet med FN’s verdensmål. Det afspejler sig i forskning, undervisning og afgangsprojekter. Dette projekt har forholdt sig til følgende FN-mål